Shrink film rolls have become an indispensable resource in various industries, from packaging and shipping to food preservation and retail. According to a report by Smithers Pira, the global shrink film market was valued at approximately $6.4 billion in 2021 and is projected to reach $8.2 billion by 2026, showcasing the increasing demand for efficient and protective packaging solutions. This remarkable growth highlights the significance of understanding the technology and applications behind shrink film roll products.

As businesses strive for sustainability and efficiency, knowing the key facts about shrink film rolls can enhance operational practices and contribute to a more effective packaging strategy. In this blog, we will explore ten amazing facts about shrink film rolls that every professional should know, helping you stay informed about the latest developments and best practices in the industry.

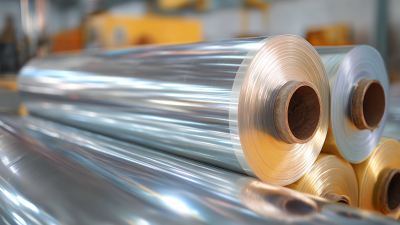

Shrink film rolls are an essential packaging solution that offers a multitude of benefits for businesses and consumers alike. The primary purpose of shrink film is to create a tight seal around products, providing protective coverage that is both secure and visually appealing. This type of packaging helps to safeguard items from dust, moisture, and physical damage, ensuring they arrive at their destination in pristine condition. Whether it's for retail products, food items, or industrial applications, shrink film efficiently wraps and preserves a wide variety of shapes and sizes.

In addition to protection, shrink film rolls enhance the presentation of products. The clear, glossy finish allows consumers to view the packaged items clearly while also promoting brand visibility. With the ability to use custom graphics and designs, businesses can elevate their branding efforts, making their products more enticing on store shelves. Furthermore, shrink film is lightweight, reducing shipping costs and minimizing environmental impact when compared to heavier packaging materials. Overall, the versatility and efficiency of shrink film rolls make them a valuable asset in the packaging industry.

Shrink film is a versatile packaging material widely used across various industries, but understanding the different types of shrink film materials is essential for maximizing efficiency and effectiveness in your packaging processes. The most common types are polyolefin, PVC, and polyethylene. According to a report by Smithers Pira, the global shrink film market is projected to reach 3.4 million tons by 2024, indicating strong demand and growth driven by the food and beverage sector. Each material offers distinct advantages: polyolefin is often favored for its excellent clarity and strength, making it ideal for retail packaging; PVC offers cost-effectiveness but may not suit applications requiring high temperature resistance; while polyethylene is commonly used for applications needing a softer and more flexible solution.

Shrink film is a versatile packaging material widely used across various industries, but understanding the different types of shrink film materials is essential for maximizing efficiency and effectiveness in your packaging processes. The most common types are polyolefin, PVC, and polyethylene. According to a report by Smithers Pira, the global shrink film market is projected to reach 3.4 million tons by 2024, indicating strong demand and growth driven by the food and beverage sector. Each material offers distinct advantages: polyolefin is often favored for its excellent clarity and strength, making it ideal for retail packaging; PVC offers cost-effectiveness but may not suit applications requiring high temperature resistance; while polyethylene is commonly used for applications needing a softer and more flexible solution.

When selecting shrink film, consider factors such as the product’s temperature sensitivity and the required seal strength. Here’s a tip: always run tests with different film types to determine the best fit for your needs. Additionally, be mindful of sustainability; many manufacturers are now offering recyclable shrink films, which can help reduce your environmental impact. Integrating greener practices not only enhances your brand's reputation but can also appeal to eco-conscious consumers, further driving sales.

Shrink film is an essential material in the packaging industry, offering both protection and aesthetic appeal. Proper usage is crucial for maximizing its benefits. According to a study by Freedonia Group, the demand for shrink film is projected to reach over $2 billion by 2025, largely due to its versatility in various sectors, including food and beverage, pharmaceuticals, and consumer goods. To ensure optimal results, it is vital to select the appropriate type of shrink film—polyolefin and PVC are the most common, each with unique qualities suited for different applications.

When employing shrink film for packaging, the process starts with adequate heat sealing. The film should completely envelop the product, leaving no gaps to prevent moisture or contaminants. A report from Smithers Pira highlights that perfecting the shrink wrap process can reduce packaging waste by up to 30%, which is significant in terms of sustainability. Furthermore, utilizing heat tunnels properly can increase efficiency, ensuring that the shrink film conforms tightly around the package without compromising its integrity. By following these guidelines, businesses can enhance both the functionality and aesthetic appeal of their products in a competitive market.

This chart illustrates the distribution of shrink film usage across various industries. The retail packaging sector leads with 25% usage, followed by food packaging at 20%. Understanding these statistics can help in selecting the right application for shrink film products.

Shrink film rolls have become indispensable across various industries due to their versatile applications and protective qualities. In the food and beverage sector, shrink film is primarily used for packaging products like bottled drinks, frozen meals, and snack items. The tightly sealed packaging not only preserves freshness but also ensures hygiene, making it ideal for items that require extended shelf life. Additionally, the clear, glossy finish of shrink film enhances product visibility, appealing to consumers and influencing purchasing decisions.

In the retail industry, shrink film rolls serve a crucial role in bundling and palletizing merchandise. Retailers often use shrink film to secure multiple products together, providing a neat and organized appearance while also protecting items from dust and damage during transit. Beyond retail, shrink film finds applications in pharmaceuticals, where it is employed to package medicines and medical devices safely. This not only safeguards the integrity of the products but also deters tampering, ensuring that consumers receive effective and safe healthcare solutions. The versatility and robustness of shrink film rolls make them an essential tool in various industrial applications.

When it comes to choosing the right shrink film for your packaging needs, understanding the various types can significantly enhance your selection process. There are several materials available, including polyolefin, PVC, and polyethylene, each with its own unique properties. Polyolefin shrink film is popular for its versatility and its ability to shrink tightly around products, providing a neat appearance. It is also suitable for temperatures that can handle various applications, making it a reliable choice for many businesses.

Another crucial factor to consider is the thickness of the shrink film. The thickness directly impacts the durability and strength of the packaging. Thicker films are more resistant to punctures and tears, ideal for heavier or more delicate items. Additionally, look out for gauge options; a lower gauge number indicates a thicker film while a higher number corresponds to a thinner film.

Lastly, don't forget to consider the shrink ratio – this is the percentage the film will shrink when heated. Understanding these key features will aid you in selecting the right shrink film that aligns with your packaging requirements, ensuring both protection and presentation.