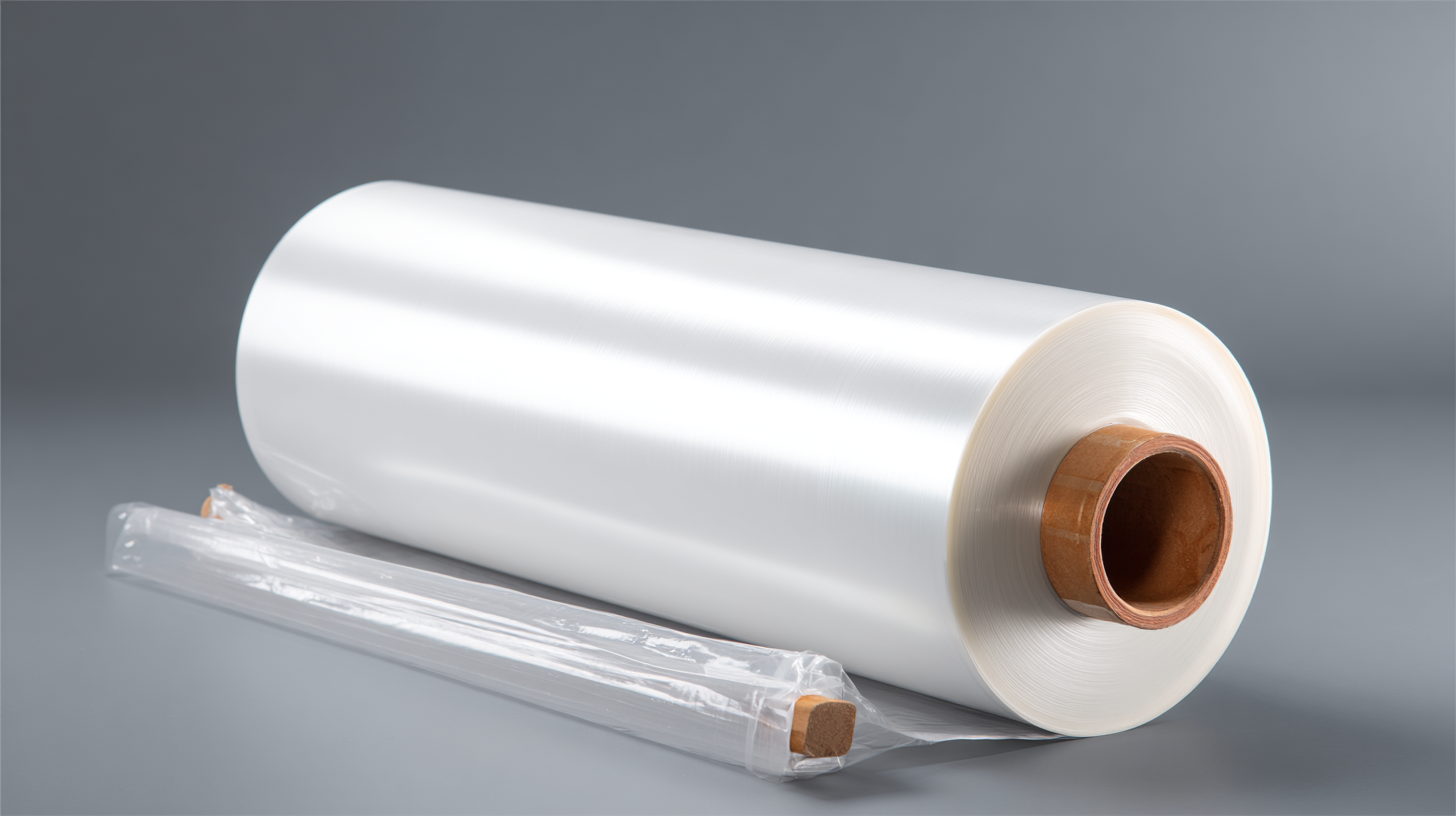

When it comes to packaging, selecting the right materials is crucial for ensuring product integrity and customer satisfaction. One essential tool in the packaging arsenal is the Shrink Film Roll, which offers versatility and protection across various industries. However, with so many options available, how do you determine which shrink film is best suited for your specific packaging needs? In this blog, we will delve into six key reasons to consider when choosing a Shrink Film Roll, including the type of product being packaged, the required durability, and the environmental impact. By understanding these factors, businesses can make informed decisions that not only enhance the safety and aesthetic of their products but also streamline their packaging processes. Join us as we explore the important aspects of selecting the perfect shrink film for your unique applications.

When selecting the right shrink film for your packaging needs, understanding the different types available is essential. Shrink films are categorized primarily into PVC, Polyolefin, and PE, each with unique characteristics and applications. According to a report by Smithers Pira, the global shrink film market is expected to reach $9.69 billion by 2024, driven by the growing demand for efficient packaging solutions across various industries including food and beverages, pharmaceuticals, and personal care.

Choosing the right shrink film for your packaging needs is essential for ensuring product safety and presentation. Key factors to consider include the type of product, shrink film material, and environmental impact.

Polyolefin, for instance, is widely favored for its superior clarity and strength, making it ideal for retail packaging. According to a report by Smithers Pira, the global shrink film market is expected to reach $11.5 billion by 2024, driven by increasing demand across various sectors, including food and beverage.

Another critical factor is the size and shape of your product. When selecting shrink film rolls, consider the film’s gauge and shrink percentage, as these affect how well it conforms to your item. Films with a higher shrink percentage tend to provide better support for irregular shapes, while films between 60-100 gauge are typically ideal for most packaging needs. Moreover, evaluate the environmental considerations; for instance, many consumers now prefer recyclable options. Choosing materials that meet these demands can enhance your brand’s reputation and align with market trends that place a premium on sustainability.

When selecting shrink film for packaging needs, understanding the balance between thickness and strength is crucial. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), the ideal thickness for shrink film typically ranges from 50 to 100 microns. Thicker films provide greater durability but can be more challenging to work with due to their rigidity. Conversely, thinner films are more flexible but may sacrifice some strength, particularly under heavy loads.

Tips for balancing thickness and strength include conducting performance tests on samples before making a bulk purchase. Testing for puncture resistance and clarity can provide insight into how the film will behave during shipping and on store shelves. A study by the Flexible Packaging Association indicated that using the appropriate film thickness can reduce shipping costs by up to 30%, making it essential to find that sweet spot.

Additionally, consider the environmental conditions your product will face. If your products are susceptible to moisture or heat, a stronger, thicker film may provide the necessary protection. Opting for co-extruded films can also enhance strength while maintaining flexibility, ensuring that your packaging performs effectively in various environments.

When selecting shrink film for packaging, evaluating its heat tolerance in relation to environmental conditions is crucial. Different products and settings require varying levels of thermal resistance. For example, if a packaged item is exposed to high temperatures during shipping or storage, it’s essential to choose a shrink film that maintains integrity without warping or compromising the packaging. Films like PVC and polyolefin offer unique properties suited for various scenarios; while PVC is often more economical, polyolefin is known for its superior clarity and heat resistance.

In humid or cold environments, the heat tolerance of the shrink film becomes even more significant. Films with a higher shrink-temperature threshold ensure that packages remain tight and secure, regardless of external factors such as moisture or temperature fluctuations. For products that will encounter refrigeration or freezing, opting for films that function well in lower temperatures can prevent brittleness and ensure consistent performance. Understanding these factors will help ensure a functional and appealing presentation of packaged goods, tailored to meet specific conditions while safeguarding product integrity.

Choosing the right shrink film roll for your packaging needs is crucial for optimizing efficiency and sustainability. Recent industry trends indicate a significant shift towards eco-friendly packaging solutions. For instance, sustainable shrink films are not only designed to reduce plastic waste but also enhance product protection and shelf life. Reports show that the End of Line Packaging Industry is projected to grow from USD 6.4 billion in 2025 to USD 9.28 billion by 2034, driven by innovations in packaging materials.

When selecting a shrink film roll, consider the material's impact on your overall efficiency. Tip one: Opt for films with high puncture resistance and load stability, which can significantly reduce product damage during transit. Tip two: Evaluate the recyclability of the film; choosing options that promote easy recycling can bolster your sustainability efforts. Additionally, utilizing technologies that monitor wrapping machine performance can optimize production flow and minimize material costs.

By aligning your packaging choices with these tips, you not only enhance operational efficiency but also contribute to a greener planet.

| Criteria | Recommended Options | Benefits | Applications |

|---|---|---|---|

| Material Type | PVC (Polyvinyl Chloride) | Cost-effective, good shrink ratio | Retail products, food packaging |

| Shrink Temperature | Low-temperature shrink film | Minimizes heat damage | Delicate items, confectionery |

| Thickness | 75 to 100 gauge | Durability and puncture resistance | Heavy items, industrial goods |

| Stretchability | High stretch film | Flexible, conforms to product shape | Oddly shaped products, irregular items |

| Clarity | Crystal clear film | Enhanced product visibility | Display items, gift packaging |