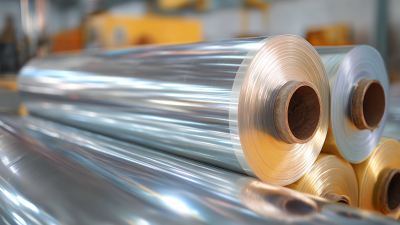

Shrink Film Packaging plays a crucial role in the global market, providing an effective solution for product protection, branding, and convenience. According to a recent report by Smithers Pira, the global shrink film market is projected to reach $8.36 billion by 2023, driven by rising demand in various industries, including food and beverage, pharmaceuticals, and consumer goods. As businesses expand their reach into international markets, selecting the right type of shrink film packaging becomes essential to meet diverse regulatory requirements and consumer preferences. Factors such as material composition, sealing properties, and environmental impact are vital in making an informed decision. This blog aims to guide manufacturers and retailers in navigating the complexities of shrink film packaging to enhance product safety and appeal in the competitive marketplace.

When selecting shrink film packaging for products, especially in the rapidly growing milk packaging sector, several key factors should be taken into account. The global milk packaging market is projected to expand from $7.07 billion in 2025 to $10.53 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.85%. This remarkable growth highlights the importance of efficient and effective packaging solutions that not only protect the product but also enhance its shelf appeal.

One of the primary considerations is the material used in shrink films, as it directly impacts the product's preservation and visual presentation. Consideration should be given to the film’s barrier properties, which influence the product's shelf life, particularly in dairy products. Additionally, ease of application is crucial in a high-volume production environment, ensuring that the packaging process remains efficient without compromising quality. Finally, sustainability is becoming increasingly relevant, with consumers and businesses alike prioritizing eco-friendly packaging solutions. Thus, selecting a shrink film that aligns with sustainability goals can also be a significant factor in building brand loyalty and meeting regulatory requirements.

When selecting shrink film packaging for global distribution, understanding the importance of material types is crucial. Different products require different levels of protection, durability, and visibility. For instance, polyethylene (PE) is commonly used for its flexibility and strength, making it ideal for packaging a variety of consumer goods. In contrast, polyvinyl chloride (PVC) offers excellent clarity and aesthetics, which can enhance product presentation on retail shelves. Knowing these characteristics helps businesses choose the right shrink film that caters to their specific needs.

Moreover, the climate and environmental regulations in various regions can influence material choice. In hot and humid environments, high-performance films that can withstand heat and moisture are essential to maintain product integrity. Additionally, sustainability has become a significant concern globally. Companies are increasingly adopting biodegradable and recyclable materials to align with eco-friendly practices. As businesses expand into international markets, selecting the appropriate shrink film packaging that considers both product needs and environmental implications will enable them to sustainably reach consumers around the world.

| Material Type | Benefits | Applications | Environmental Impact |

|---|---|---|---|

| PVC (Polyvinyl Chloride) | Cost-effective, excellent clarity | Retail packaging, bundling | Potential toxic release, low recyclability |

| PE (Polyethylene) | High versatility, good seal strength | Food products, consumer goods | Generally recyclable, lower toxicity |

| PP (Polypropylene) | High resistance to temperature, strong | Durable packaging, food containers | Recyclable, lower environmental impact |

| PLA (Polylactic Acid) | Biodegradable, renewable resource | Eco-friendly products, compostable packaging | Low impact, compostable under industrial settings |

When selecting shrink film packaging for your products, avoiding common mistakes can significantly impact your efficiency and product presentation. One frequent misstep is neglecting to consider the specific requirements of your products. Different items demand varying levels of protection, visibility, and shelf appeal, so ensure you choose a shrink film that aligns with the nature of your product. For example, heavy-duty films are essential for robust items, while lighter films may suffice for delicate products.

Another critical error is overlooking compatibility with the shrink equipment. Ensuring that the shrink film you choose works well with your existing machinery can save time and reduce issues. Incompatible films may lead to production delays and increased costs. Additionally, many companies fail to factor in the sustainability of their packaging choices. With increasing consumer awareness surrounding environmental impact, selecting eco-friendly shrink films can enhance your brand reputation and appeal to a broader audience. By being aware of these pitfalls, you can streamline your packaging process and create a more appealing product presentation.

When it comes to international shipping, selecting the appropriate shrink film packaging can significantly enhance the protection and presentation of your products. Shrink film not only offers a durable barrier against moisture and dust but also provides a custom fit that reduces the risk of damage during transit. This is particularly vital for businesses aiming to maintain product integrity while adhering to stringent shipping regulations across borders.

One of the primary benefits of shrink film packaging is its lightweight nature, which can help lower shipping costs. By reducing the overall weight of your packages, you not only save on shipping fees but also contribute to more sustainable practices by lowering carbon emissions associated with transportation. Furthermore, the clear visibility provided by shrink film enables easy product identification, facilitating smoother customs clearance and reducing delays.

Tip: Always choose a shrink film that is compliant with international standards, which can vary by destination. This ensures that your packaging meets the necessary requirements and can prevent costly fines or shipment returns. Additionally, consider using printed shrink film that showcases your brand’s logo; this not only enhances brand visibility but also creates a professional look that appeals to consumers globally.

When selecting shrink film packaging for your products, it’s crucial to assess shrink film performance based on specific product needs. A recent Frost & Sullivan report estimates that the global shrink film market will reach $4.6 billion by 2025, driven by the growing demand in end-use industries like food and beverage, pharmaceuticals, and consumer goods. The essential factors to consider include shrinkage capability, clarity, thickness, and seal strength, which directly impact product protection and shelf appeal.

Tips for Assessment:

By understanding these performance metrics, businesses can make informed decisions that align with their product requirements and enhance overall packaging effectiveness.