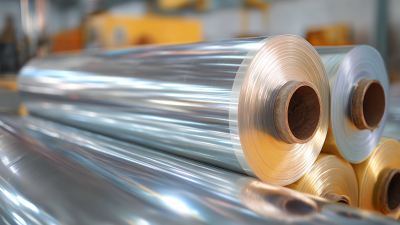

In the competitive world of packaging, companies continuously seek innovative solutions to enhance product protection and presentation. One highly effective method that has gained popularity is the use of "Shrink and Wrap" techniques. This approach involves encasing products with plastic films that shrink tightly around the item when heat is applied, resulting in a snug, secure fit that not only safeguards against damage but also provides an attractive appearance.

Whether you are a small business owner looking to improve your shipping processes or part of a larger operation aiming for efficient packaging solutions, understanding how to effectively utilize Shrink and Wrap is crucial. In this guide, we will explore the various applications, techniques, and benefits of Shrink and Wrap, enabling you to optimize your packaging strategy and meet the evolving needs of your customers.

Shrink and wrap packaging plays a crucial role across numerous industries, providing essential benefits such as protection, shelf-life extension, and marketing appeal. According to a recent report by Smithers Pira, the global shrink film market was valued at approximately $10.6 billion in 2020 and is projected to reach $14.2 billion by 2025, indicating a robust growth fueled by demand in sectors like food and beverage, pharmaceuticals, and consumer goods. This trend underscores the versatility of shrink and wrap packaging in addressing the specific needs of various industries.

When implementing shrink and wrap packaging, businesses can enhance their efficiency and output by following a few key tips. First, always select the right film type for your specific product; for example, food items often require multilayer films to ensure freshness and safety. Second, invest in quality machinery that can handle the volume and meet production needs without sacrificing the integrity of the packaging. Finally, consider the environmental impact by opting for recyclable or biodegradable films, as consumers increasingly prefer sustainable choices.

In industries such as pharmaceuticals where product integrity is paramount, the use of shrink and wrap not only secures individual items but also facilitates compliance with regulatory standards. Understanding the particulars of shrink and wrap methods ensures that businesses can deliver products safely and effectively, reinforcing their brand's reputation in a competitive marketplace.

Shrink and wrap packaging has become a cornerstone for effective product protection and branding across various industries. According to a report by Smithers Pira, the global shrink sleeve market is expected to grow by 5.5% annually, reaching nearly $35 billion by 2025. This growth can be attributed to the increasing demand for tamper-evident and moisture-proof packaging options that ensure product integrity and enhance shelf life. Shrink film provides a snug fit around products, minimizing the risk of damage during transportation, and effectively shielding them from environmental factors.

Moreover, shrink and wrap packaging plays a significant role in branding and marketing. A recent study by Fortune Business Insights indicates that visually appealing packaging can lead to a 70% increase in consumer interest, making it a crucial touchpoint for businesses. By utilizing vibrant colors and printing high-resolution graphics on shrink labels, products not only catch the eye of customers but also communicate brand identity and values effectively. Businesses harness these benefits to create a stronger presence in competitive markets, ultimately driving sales and customer loyalty.

In analyzing the cost-effectiveness of shrink and wrap packaging compared to traditional methods, it's essential to consider both economic and environmental impacts. Shrink and wrap mechanisms often provide significant advantages, reducing material use while enhancing product visibility and protection. Recent industry reports indicate that pouches, a leading form of flexible packaging, constitute over 31.8% of the market, primarily due to their versatility and consumer appeal. This statistic underscores the broader trend towards innovative packaging solutions that not only meet consumer demands but also contribute to operational efficiencies.

Moreover, the environmental implications of packaging choices cannot be overlooked. Conventional plastic packaging is increasingly scrutinized due to its contribution to non-biodegradable waste and marine pollution. Research has highlighted the escalating impact of plastic waste, prompting a shift towards sustainable alternatives, including biopolymer films. These materials offer promising benefits for lowering the lifecycle environmental footprint of packaging, with several studies showing reduced costs associated with marine ecosystem services when transitioning to biodegradable solutions. As the market for sustainable packaging continues to expand, driven by regulatory pressures and consumer preferences, companies must carefully weigh the cost-effectiveness of shrink and wrap versus traditional methods, aligning economic viability with environmental responsibility.

| Packaging Method | Material Cost (per unit) | Labor Cost (per unit) | Time Efficiency (units/hour) | Disposal Cost (per unit) | Overall Cost Effectiveness |

|---|---|---|---|---|---|

| Shrink Wrap | $0.15 | $0.05 | 120 | $0.02 | Highly Effective |

| Traditional Packaging | $0.25 | $0.10 | 80 | $0.05 | Moderately Effective |

| Pallet Wrap | $0.18 | $0.07 | 100 | $0.03 | Effective |

| Boxing | $0.30 | $0.12 | 70 | $0.06 | Least Effective |

When selecting machinery for shrink and wrap operations, it is vital to consider the specific requirements of your packaging process. Analyze the volume of products to be packaged, the types of materials used, and the expected production speed. Different machines offer varied capabilities, such as manual, semi-automated, and fully automated solutions. A semi-automated machine can provide flexibility for diverse product sizes, while fully automated systems enhance efficiency in high-volume scenarios. Assessing these factors will help you choose the right machine, ensuring optimal performance and cost-effectiveness.

Maintenance is equally crucial in maintaining the efficiency and longevity of your shrink and wrap machinery. Regularly inspect the equipment for wear and tear, focusing on critical components such as heating elements, conveyors, and sealing bars. Establish a routine maintenance schedule that includes cleaning, lubrication, and part replacement as needed. Additionally, training your staff on proper machine operation can help minimize operational issues and extend the lifespan of your equipment. By prioritizing both machine selection and regular maintenance, you can significantly enhance the effectiveness of your shrink and wrap operations.

Sustainability has become a crucial consideration in packaging solutions, and shrink and wrap technologies are no exception. As consumers increasingly demand eco-friendly alternatives, manufacturers are compelled to explore materials that minimize environmental impact. Biodegradable and compostable films are gaining popularity, as they not only serve the traditional functions of shrink and wrap but also break down naturally, reducing landfill waste. These materials can offer the same durability and aesthetic appeal while significantly lowering the carbon footprint.

Moreover, businesses can adopt practices such as using recycled content in their shrink and wrap films. Innovations in material science have led to the development of films made from recycled plastics, which help close the loop on plastic usage. Additionally, implementing efficient packaging processes can further enhance sustainability. Techniques like optimizing shrink wrap sizes to minimize excess material and utilizing energy-efficient machinery can contribute to both environmental responsibility and cost savings. By integrating these sustainable options, companies can not only meet regulatory standards but also appeal to eco-conscious consumers, fostering a responsible brand image.