In the world of packaging, ensuring product safety and presenting an appealing appearance are crucial for success, and one essential tool that stands out in achieving these goals is Plastic Wrap Shrink. This versatile material not only provides a protective barrier against environmental factors, but it also tightens to fit snugly around items, enhancing both stability and aesthetics. As we delve into the best practices for utilizing Plastic Wrap Shrink in your packaging process, we will explore innovative techniques and tips that can elevate your packaging strategy. From improving efficiency to reducing waste, mastering the use of Plastic Wrap Shrink can lead to significant benefits for your business, ensuring your products not only survive transit but also look their best on the shelves.

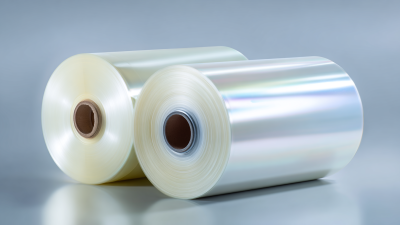

Plastic wrap shrink, often known as shrink film, has revolutionized the packaging industry with its versatility and effectiveness. Understanding the basics of this material is key to leveraging its benefits. Shrink film is a thermoplastic layer that, when exposed to heat, shrinks tightly around the product it envelops. This ensures a secure fit, protecting items from dust, moisture, and physical damage. The process not only enhances the appearance of packaged goods but also extends their shelf life, making it a favorite for retailers and manufacturers alike.

To effectively use plastic wrap shrink, it's essential to choose the right type based on the product requirements. Different shrink films have varying thicknesses, shrink ratios, and clarity levels. A well-selected film will not only provide visual appeal but also durability during transportation and handling. Furthermore, mastering the application technique is crucial; using heat guns or shrink tunnels ensures a smooth, bubble-free seal. Proper training for staff handling this equipment can lead to increased efficiency and improved packaging integrity, ultimately contributing to packaging success in any business.

When it comes to packaging, selecting the appropriate type of plastic wrap shrink is crucial for ensuring product safety and presentation. According to the Flexible Packaging Association, the flexible packaging market is expected to exceed $300 billion by 2026, indicating a growing reliance on materials like shrink wrap. This material is not just about aesthetics; it serves as a barrier against moisture, dust, and contaminants, which can significantly prolong shelf life and enhance product quality.

When choosing the right plastic wrap shrink, businesses must consider factors such as thickness, cling properties, and temperature tolerance. For instance, a study by the Institute of Packaging Professionals revealed that using high-quality polyethylene shrink film can reduce product waste by up to 20% due to better protection during transit. Additionally, opting for biodegradable or recyclable options can align with sustainability goals while appealing to environmentally conscious consumers. By carefully assessing these elements, companies can optimize their packaging processes and achieve greater success in their market strategies.

When using plastic wrap shrink for packaging, proper application is crucial for achieving a professional finish. First, ensure that the surface to be wrapped is clean and dry, as contaminants can hinder adhesion and compromise the seal. Begin by cutting your plastic wrap to the desired length, allowing for a bit of overlap on all sides. According to a report by Freedonia Group, the demand for shrink film packaging is expected to reach $6.2 billion by 2024, highlighting the importance of effective application in a competitive market.

Next, place the item in the center of the plastic wrap, pulling the film taut to eliminate wrinkles. Use a heat source, such as a heat gun or shrink tunnel, to evenly distribute heat across the wrap. It's essential to monitor the temperature to avoid melting or damaging the product. Data from Smithers Pira indicates that correct application can increase packaging efficiency by up to 25%, ultimately reducing wastage and enhancing product integrity. By mastering these steps, businesses can ensure their products are securely packaged, minimizing damage during transit and maximizing customer satisfaction.

When using plastic wrap shrink for packaging, avoiding common mistakes can significantly enhance your results. One frequent error is not preparing the item properly before wrapping. Ensure that the surface of the product is clean and dry; any dust or moisture can prevent the plastic from adhering correctly, leading to a less secure seal and, ultimately, compromised packaging integrity.

Another common oversight is applying the plastic wrap too tightly. While it may seem intuitive to pull the wrap snugly, excessive tension can cause it to tear or distort, affecting both appearance and functionality. Instead, aim for a balanced application, allowing some slack to accommodate shrinkage during the heating process.

Finally, neglecting to test your heat source can lead to inconsistent results. Different plastics require various temperatures to shrink effectively. Conducting a small heat test on a similar material before proceeding can help ensure optimal shrinkage without damaging your product. By heeding these tips, you can enhance your packaging efficiency and ensure a more professional finish.

Plastic wrap shrink, often overlooked in packaging discussions, offers numerous advantages that can enhance efficiency and sustainability in various industries. According to a report by Grand View Research, the global shrink packaging market was valued at over $12 billion in 2020 and is projected to grow at a CAGR of 4.5% from 2021 to 2028. This growth is attributed to the rising demand for efficient packaging solutions that not only protect products but also enhance shelf appeal.

One of the most significant benefits of using plastic wrap shrink is its ability to provide a tight, protective seal around products. This not only prevents moisture and contaminants from affecting the item but also minimizes the risk of damage during transportation. A study by the Flexible Packaging Association revealed that packaging that incorporates shrink technology can reduce product spoilage by up to 70%, making it an invaluable option for food and beverage manufacturers. Moreover, the lightweight nature of shrink film contributes to lower shipping costs, as less weight means reduced fuel consumption in transport logistics.

Additionally, plastic wrap shrink is environmentally friendly compared to traditional packaging methods. Research from the Packaging Association indicates that materials used for shrink wrapping can be recycled at a rate exceeding 40%, promoting a circular economy. As companies increasingly adopt sustainable practices, integrating plastic wrap shrink into their packaging strategies not only aligns with environmentally responsible initiatives but also meets consumer demand for eco-conscious products.

| Aspect | Description | Benefits |

|---|---|---|

| Protection | Shrinking the wrap creates a snug fit around the product, protecting it from dust, moisture, and contamination. | Enhances product integrity and increases shelf-life. |

| Cost-Effectiveness | Plastic wrap shrink is generally low-cost compared to other packaging materials. | Reduces overall packaging expenses while maintaining quality. |

| Versatility | Can be used for a wide range of products, including food items, electronics, and gift items. | Flexible for various industries and product types. |

| Visual Appeal | Provides a clear view of the product with a clean, professional finish. | Attracts customers and enhances branding. |

| Environmental Considerations | Using recyclable plastic materials can lessen environmental impact. | Promotes sustainability in packaging solutions. |