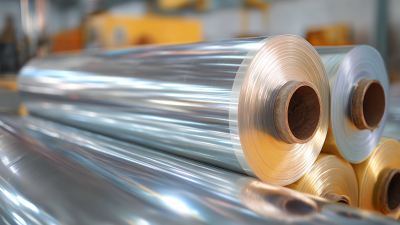

Shrink wrap is a versatile packaging solution that has gained popularity across various industries for its effectiveness in protecting products during storage and transportation. According to a recent market report by Allied Market Research, the global shrink wrap market is projected to reach $3.2 billion by 2027, growing at a CAGR of 4.5% from 2020 to 2027. This rapid growth highlights the increasing demand for efficient wrapping materials that can safeguard items from dust, moisture, and contamination. With its ability to conform tightly to the shape of packaged goods, shrink wrap not only enhances visual appeal but also provides tamper-evidence, ensuring product integrity. In this guide, we will explore the best practices for effectively using shrink wrap, offering insights into maximizing its protective qualities and optimizing packaging processes for a diverse range of products.

Shrink wrap is a versatile packaging solution that has gained popularity across various industries for its effectiveness in protecting products during storage and transportation. According to a recent market report by Allied Market Research, the global shrink wrap market is projected to reach $3.2 billion by 2027, growing at a CAGR of 4.5% from 2020 to 2027. This rapid growth highlights the increasing demand for efficient wrapping materials that can safeguard items from dust, moisture, and contamination. With its ability to conform tightly to the shape of packaged goods, shrink wrap not only enhances visual appeal but also provides tamper-evidence, ensuring product integrity. In this guide, we will explore the best practices for effectively using shrink wrap, offering insights into maximizing its protective qualities and optimizing packaging processes for a diverse range of products.

When selecting the right type of shrink wrap for your packaging needs, it is crucial to consider the specific requirements of the items you intend to protect. According to a report by Smithers Pira, the global market for shrink film is projected to reach $4.6 billion by 2024, underscoring the importance of choosing the appropriate material for efficiency and effectiveness in packaging. Different types of shrink wraps, such as PVC, polyethylene, and polypropylene, offer varying levels of durability, clarity, and environmental impact. For instance, polyethylene shrink film is highly resistant to moisture and UV exposure, making it ideal for outdoor applications, while PVC provides a stronger barrier against punctures and tears.

In addition to material choice, understanding the thickness and shrink ratio is key to optimizing performance. The American Plastics Council indicates that a shrink wrap with a thickness of 60 to 75 gauge is commonly used for retail applications, providing adequate protection while keeping costs manageable. Furthermore, the shrink ratio can significantly impact the final appearance and integrity of the package; a higher shrink ratio is typically preferable for irregularly shaped products, as it allows for a snug fit that minimizes movement and damage during transit. Ultimately, identifying the right type of shrink wrap involves careful consideration of these factors to ensure your products are adequately protected and presented.

Preparing items for shrink wrapping requires careful attention to best practices to ensure the effectiveness and sustainability of packaging. First and foremost, it is essential to clean the items thoroughly to remove any dust or grease that could interfere with the adhesion of the shrink wrap.

Organizing items in a way that optimizes space can help minimize waste and ensure a snug fit, which not only preserves the items better but also reduces excess material use.

Preparing items for shrink wrapping requires careful attention to best practices to ensure the effectiveness and sustainability of packaging. First and foremost, it is essential to clean the items thoroughly to remove any dust or grease that could interfere with the adhesion of the shrink wrap.

Organizing items in a way that optimizes space can help minimize waste and ensure a snug fit, which not only preserves the items better but also reduces excess material use.

As companies transition toward more sustainable practices, selecting eco-friendly shrink wrap alternatives is critical. This shift is seen in various industries as businesses prioritize reducing their carbon footprint. It is beneficial to consider materials that are recyclable or biodegradable, ensuring that the packaging not only protects the items but also aligns with broader environmental goals. By implementing these best practices, businesses can enhance their packaging strategies while contributing positively to sustainability efforts.

Shrink wrapping is an effective method for packaging and protecting products, and mastering the technique can enhance your packaging process significantly. To begin, gather the necessary materials: shrink wrap film, a heat source (like a heat gun or shrink wrap machine), scissors, and a work surface. Start by measuring and cutting the shrink wrap to fit your product, leaving enough excess material around the edges for a secure seal.

Place your product in the center of the cut film and pull the edges over it, ensuring a snug fit.

Place your product in the center of the cut film and pull the edges over it, ensuring a snug fit.

Next, use your heat source to shrink the wrap tightly around the product. If you’re using a heat gun, keep it at a safe distance to avoid overheating the film. Move the gun in a circular motion until the wrap conforms smoothly around the product. For large items, a shrink wrap machine can streamline the process by applying heat evenly and automatically sealing the wrap. Once completed, inspect the wrapped product for any holes or unevenness and ensure it's properly sealed. This method not only secures items for shipping but also provides moisture resistance and adds a professional appearance to your packaging.

Shrink wrapping is an efficient method for packaging products while providing protection from dust, moisture, and abrasion. Mastering the operation of shrink wrapping equipment is crucial to achieving professional results. Here are some tips to help you operate shrink wrapping equipment effectively.

First, always ensure that your workstation is clean and organized. A clutter-free environment will reduce the risk of accidents and improve workflow. Check the equipment for any wear and tear before starting your project. Regular maintenance, such as cleaning the sealing bars and replacing worn parts, will enhance performance and prolong the lifespan of your shrink wrapping machine.

Secondly, choose the right shrink wrap material for your products. Factors like thickness, clarity, and shrink ratio should be considered based on your packaging needs. Additionally, set the correct temperature on your heat gun or shrink tunnel to avoid over or under-shrinking, which can lead to poor sealing or product damage. Finally, always practice safety precautions, such as wearing gloves and goggles, to protect against heat and sharp edges during operation.

| Tip | Description | Benefits |

|---|---|---|

| Choose the Right Film | Select a shrink film that suits the product dimensions and purpose. | Ensures optimal protection, appearance, and enhances shelf life. |

| Adjust Temperature Settings | Experiment with the shrink tunnel and heat settings to achieve a perfect seal. | Preventing over or under-shrinking, improves packaging efficiency. |

| Ensure Proper Product Placement | Position items correctly in the film to ensure full coverage and protection. | Minimizes risk of damage during transit and improves aesthetic appeal. |

| Maintain Equipment Regularly | Perform routine checks and maintenance on the shrink wrap machine. | Increases machinery lifespan and reduces risks of malfunctions. |

| Use Appropriate Cooling Time | Allow the products to cool before handling them after shrink wrapping. | Prevents condensation and provides a tighter seal. |

| Test Samples | Run tests on sample products to perfect the shrink wrap process. | Ensures quality assurance and identifies issues before mass production. |

When it comes to maintaining and storing shrink-wrapped items, proper techniques can significantly extend the life and quality of your products.

The key is to keep the items in a cool, dry place, away from direct sunlight and moisture. Excess heat can cause the shrink wrap to become brittle, while humidity can lead to mold growth. For items that are frequently accessed, consider using clear shrink wrap to allow for visibility without unpacking.

Tips: Always inspect your shrink-wrapped items periodically for any signs of damage or wear. If you notice any punctures, rewrap the item to ensure continued protection. Additionally, store heavier items at the bottom to prevent crushing lighter items above, which could compromise their integrity.

For long-term storage, it's beneficial to use a desiccant pack in the storage area to minimize moisture. Ensure that the wrap is tight but not overly compressed, as this can create pressure points that may damage the contents. Proper organization and labeling of shrink-wrapped items can also streamline retrieval and help maintain order in your storage space.