In the fast-paced world of logistics and packaging, the use of Stretch Film has become increasingly vital for businesses aiming to enhance efficiency and ensure the safe transportation of goods. According to a report by Technavio, the global stretch film market is projected to grow by over $3 billion between 2021 and 2025, driven by the rising demand for effective packaging solutions and the need for stronger protection against contamination and damage. With its ability to tightly wrap products and stabilize loads, Stretch Film not only minimizes the risk of accidents during transit but also reduces overall packaging waste. Mastering the best practices in Stretch Film application can significantly impact operational effectiveness, making it essential for industries to leverage this valuable packaging resource effectively. In this blog, we will explore seven essential tips for using Stretch Film like a pro, ensuring that your goods are secured and your packaging processes are optimized.

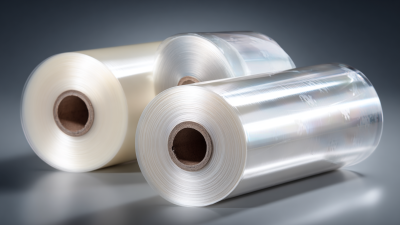

When it comes to choosing the right stretch film for your packaging needs, understanding the different types available is crucial. Stretch film generally falls into two main categories: machine stretch film and hand stretch film.

Machine stretch film is designed for automated systems and offers superior tensile strength and clarity, making it ideal for high-volume operations. This type is typically used in warehouses and distribution centers, where efficiency and speed are paramount. Conversely, hand stretch film is perfect for smaller scale applications and is easy to use without the need for machine assistance. This makes it a favorite among small businesses and individual users.

Machine stretch film is designed for automated systems and offers superior tensile strength and clarity, making it ideal for high-volume operations. This type is typically used in warehouses and distribution centers, where efficiency and speed are paramount. Conversely, hand stretch film is perfect for smaller scale applications and is easy to use without the need for machine assistance. This makes it a favorite among small businesses and individual users.

Additionally, stretch films vary by thickness, which affects their strength and stretchability. Thicker films (often referred to as 80 gauge or higher) provide enhanced durability and puncture resistance, making them suitable for heavier loads. In contrast, lighter films (like 60 gauge) are sufficient for lighter items and offer more stretch, which can be beneficial when wrapping irregularly shaped products.

Understanding these variations allows you to select a film that not only meets your operational demands but also optimizes costs, ensuring you get the best performance from your stretch film application.

Proper application of stretch film is crucial for efficient packaging, particularly in industries such as agriculture and food distribution. Mastering the right techniques not only enhances the effectiveness of the stretch film but also ensures products remain secure during transport. For starters, understanding the appropriate amount of film tension is vital. Excessive force can cause tears, while insufficient tension may lead to load instability.

Additionally, utilizing a systematic wrapping technique can optimize the packing process. Start by anchoring the film to the base of your load, ensuring a firm grip before moving upwards in a figure-eight pattern. This method effectively covers the entire load while distributing pressure evenly, preventing shifting during transit.

As demonstrated by innovative techniques in the agricultural sector, such as those implemented by tomato growers, applying stretch film proficiently can lead to significant improvements in packing efficiency and product integrity. Embracing these strategies not only saves time but also enhances the overall quality of the shipped goods.

When it comes to using stretch film effectively, having the right tools and equipment is essential. One of the key pieces of equipment is the hand-held stretch film dispenser. This tool not only provides better grip and control but also enables users to wrap products more efficiently. Designed with ergonomic handles, these dispensers reduce strain during the wrapping process and allow for tighter, more secure wraps.

Additionally, investing in a powered stretch film machine can significantly enhance the efficiency of large-scale operations. These machines automate the wrapping process, ensuring consistent tension and reducing film consumption while increasing throughput.

Another important aspect of enhancing your stretch film experience is to choose the right type of film for your specific needs. Whether you’re dealing with heavy industrial products or lighter packages, selecting the appropriate gauge and thickness is crucial. High-performance stretch films offer superior stretch and cling properties, allowing for secure load stabilization without over-wrapping. Furthermore, incorporating accessories such as corner protectors and edge protectors can safeguard your products during transport.

By utilizing the right tools and accessories, you can optimize your stretch film application, ensuring that your loads remain secure and undamaged throughout their journey.

When working with stretch film, avoiding common mistakes is crucial to ensure both efficiency and product protection. One frequent error is not properly tensioning the film when wrapping. Insufficient tension can lead to loose wraps that fail to secure the load, while overly tight wraps can cause the film to tear, compromising both the stability of the package and the integrity of the contents. It's essential to find the right balance to maximize both security and longevity.

Another common misstep is neglecting to choose the appropriate gauge of stretch film for the specific application. Using a film that is too thin may not provide the necessary strength for heavier loads, leading to potential damage during handling or transportation. Conversely, opting for a thicker film than needed can unnecessarily increase costs and waste material. Therefore, assessing the load and selecting the right film gauge can significantly enhance the protection afforded to your products while streamlining your packaging process.

| Tip | Description | Common Mistake |

|---|---|---|

| 1. Choose the Right Film | Select the appropriate thickness and stretch level for your items. | Using a film that is too thin for the load. |

| 2. Pre-Stretch the Film | Pre-stretching allows for improved load stability. | Skipping this step can lead to poor containment. |

| 3. Maintain Proper Tension | Control the stretch and tension for optimal wrapping. | Too much or too little tension can compromise the wrap. |

| 4. Wrap from the Bottom Up | Start wrapping at the base to ensure stability. | Wrapping from the top down can lead to uneven loads. |

| 5. Cover All Sides | Ensure all sides of the load are securely wrapped. | Neglecting edges can result in damage during transport. |

| 6. Use Equipped Tools | Utilize dispensers and cutters for efficient wrapping. | Relying solely on hands can lead to inconsistent wrapping. |

| 7. Practice Good Technique | Maintain a steady pace and rhythm to enhance quality. | Rushing the process can lead to errors in wrapping. |

When it comes to securing loads for transport or storage, stretch film is an indispensable tool that can significantly enhance load stability and protection. To maximize its effectiveness, it’s essential to understand a few fundamental techniques. Firstly, ensure that the film is tightly wrapped around the load, as this will prevent any shifting during transit. The tension applied during wrapping is crucial; too loose, and the load may collapse, too tight, and the film may tear, compromising integrity. Aim for a balance that firmly holds the items together without causing damage.

Moreover, consider the configuration of your load. Stacking boxes or crates in a staggered formation can promote better weight distribution, making it easier for the stretch film to secure everything cohesively. Using corner posts or cushioning materials in conjunction with the film can also add an extra layer of protection, preventing edges from piercing through the wrap. Lastly, remember to overlap each layer of stretch film by at least 50% to ensure consistent coverage and stability. Employing these strategies will not only safeguard your products but also streamline the shipping process, ultimately leading to greater efficiency and fewer damages.