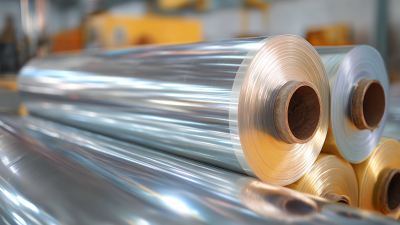

Heat Shrink Wrap is a versatile and highly effective packaging solution that offers a myriad of benefits for both professionals and DIY enthusiasts alike. In today's fast-paced market, the need for reliable packaging methods has become paramount, making it essential to understand the techniques and best practices associated with heat shrink wrap. This comprehensive guide delves into the various heat shrink wrap techniques that can enhance your packaging processes, ensuring your products remain secure, tamper-proof, and visually appealing. From selecting the right materials to mastering the application techniques, this blog will equip you with the knowledge necessary to achieve optimal packaging results. Whether you are looking to protect delicate items, streamline your shipping processes, or simply elevate your brand presentation, understanding the nuances of heat shrink wrap will empower you to make informed decisions in your packaging endeavors.

Heat shrink wrap has become an essential solution in the packaging industry, offering numerous benefits that enhance both product protection and presentation. This versatile material shrinks tightly around your items when heat is applied, creating a durable barrier against dust, moisture, and tampering. As a result, products not only remain safe during transportation but also maintain an appealing appearance on retail shelves.

To maximize the effectiveness of heat shrink wrap, it’s crucial to choose the right type based on your specific products. For instance, selecting a shrink wrap thickness that corresponds to the fragility of the item can prevent damage. Additionally, ensuring optimal heat settings during the application process will help achieve the best sealing results without compromising the integrity of the packaging.

Another important tip is to maintain a clean and organized workspace. Dust or debris can interfere with the adhesion of the shrink wrap, leading to potential failures in protection. Also, consider using labels that withstand heat to ensure all necessary information remains legible after the wrapping process. By following these best practices, businesses can harness the full potential of heat shrink wrap, improving both operational efficiency and customer satisfaction.

When it comes to heat shrink wrap, understanding the various types available can significantly enhance your packaging strategy. One of the most commonly used materials is polyolefin wrap, known for its versatility and strong sealing properties. This type offers excellent clarity and a smooth finish, making it ideal for retail products and food packaging. Its resistance to punctures and tearing ensures that items remain protected during storage and transport.

Another popular option is PVC shrink wrap, which is often used for bundling multiple products together. PVC is less expensive than polyolefin and provides good shrinkage characteristics, making it effective for packaging irregularly shaped items. However, it is important to note that PVC is not as eco-friendly as its counterparts, which can be a disadvantage for companies focusing on sustainability.

A more environmentally conscious choice is biodegradable shrink wrap, made from materials like PLA (polylactic acid), which decompose over time. This option is gaining traction among businesses that wish to reduce their ecological footprint while still enjoying the benefits of heat shrink packaging. Each of these shrink wrap types offers unique advantages that can cater to different packaging needs effectively.

Heat shrink wrap has become an essential component in the packaging industry, significantly enhancing product protection and longevity. According to a report from Smithers Pira, the global market for flexible packaging, which includes heat shrink films, is projected to grow to $260 billion by 2025. This growth is attributed to the increasing demand for protective packaging solutions that can withstand environmental factors while maintaining product integrity. Heat shrink wrap provides a tight, secure fit around products, preventing contamination, moisture, and UV damage, which is crucial for industries like food and beverage, pharmaceuticals, and electronics.

Moreover, heat shrink wrapping offers numerous advantages over traditional packaging methods. A study from the Packaging Machinery Manufacturers Institute (PMMI) indicates that heat shrink wrap can reduce product spoilage by up to 25% compared to non-shrink alternatives. This is particularly beneficial for perishables that require extended shelf life. In addition to its protective capabilities, the transparency of heat shrink materials allows consumers to view the product, enhancing visual appeal and marketing effectiveness. Through these protective measures, businesses are able to preserve product quality and reduce waste, making heat shrink wrap a practical choice for optimal packaging solutions.

Heat shrink wrap is not only a practical packaging solution but also a cost-effective choice for businesses looking to optimize their operations. The initial investment in heat shrink materials and equipment can lead to substantial savings over time. By minimizing product damage during shipping and storage, companies reduce costs related to returns and replacements, ultimately enhancing their bottom line.

**Tips:** When considering heat shrink wrap for your products, assess the volume of items you’ll be packaging. Bulk purchases of shrink wrap and tools can lead to significant discounts, so plan ahead to maximize your savings. Additionally, training staff on effective shrink wrap techniques can streamline the packaging process, reducing labor costs and increasing efficiency.

Implementing heat shrink wrap also allows for better inventory management. With products securely packaged and clearly identified, businesses can handle inventory with greater ease, minimizing the risk of errors.

**Tips:** Use the right-sized shrink wrap for your products to avoid excessive waste. Overwrapping not only increases material costs but can also impact the perception of your brand's sustainability efforts.

Heat shrink wrap is increasingly becoming a pivotal choice in sustainable packaging solutions. According to the Environmental Protection Agency (EPA), packaging contributes to nearly 30% of landfill waste in the U.S., pushing industries to seek more eco-friendly alternatives. Unlike traditional plastic wraps, heat shrink wrap is composed of materials that can be recycled more efficiently, reducing the overall carbon footprint. Research indicates that in a life cycle analysis, heat shrink materials can save up to 65% in energy consumption compared to other packaging techniques.

**Tip:** When selecting heat shrink materials, prioritize those made from recyclable plastics, such as polyethylene or PVC, to enhance sustainability.

Another sustainable aspect of heat shrink wrap is its efficiency in product protection, which minimizes the need for additional packaging materials. A study from Smithers Pira highlights that the use of heat shrink wrap can reduce the volume of packaging required by up to 40%. This not only cuts down the resources needed but also lowers transportation emissions due to lighter load weights.

**Tip:** Optimize shrink wrap use by ensuring proper sizing and applying the correct heat settings, which can reduce waste and ensure maximum efficiency.