The packaging industry is undergoing a significant transformation, propelled by technological advancements and changing consumer preferences. Among the various packaging solutions, the Shrink Packing Machine has emerged as a pivotal player, providing efficiency and enhanced product presentation. According to a report by MarketsandMarkets, the shrink packaging market is projected to grow from $31.2 billion in 2021 to $41.3 billion by 2026, reflecting a CAGR of 5.5%. This growth is driven by the increasing demand for safe and hygienic packaging solutions, particularly in food and beverage, pharmaceuticals, and consumer goods sectors.

As we look ahead to 2024, several innovative trends are set to reshape the landscape of shrink packaging, offering businesses new opportunities to improve productivity and sustainability. This blog will explore the key trends that industry stakeholders should be aware of to stay competitive in the evolving market.

As we approach 2024, the landscape of shrink packing machines is undergoing a significant transformation, largely driven by emerging technologies aimed at enhancing efficiency and sustainability. One of the most promising trends is the integration of artificial intelligence (AI) and machine learning. These technologies enable real-time monitoring and optimization of packaging processes, leading to reduced waste and energy consumption. For instance, studies show that implementing AI in manufacturing environments can boost operational efficiency by up to 30%, highlighting its impact on reducing both costs and ecological footprints.

Another noteworthy trend is the incorporation of industry 4.0 technologies, which are redefining how we approach production workflows. Smart packing solutions that utilize IoT devices can create interconnected manufacturing systems capable of tracking inventory levels and predicting maintenance needs. This not only streamlines operations but also enhances the overall supply chain efficiency. Reports indicate that adopting smart manufacturing practices can result in a 20% reduction in production time and significant improvements in resource utilization, promoting a more sustainable circular economy.

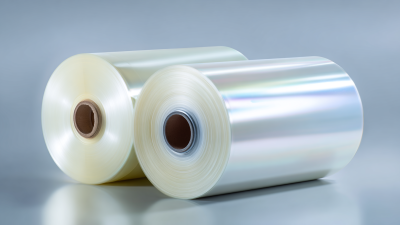

Furthermore, sustainable materials are gaining traction in shrink packing machines, aligning with a broader industry shift towards eco-friendly solutions. Innovative biodegradable films and reusable packaging materials are being developed to meet the growing consumer demand for sustainability. Recent data suggests that the market for sustainable packaging materials is expected to reach over $400 billion by 2025, indicating a clear movement towards environmentally responsible choices in packaging technologies.

The push for sustainability has become a prevailing trend in the packaging industry, and shrink packing is no exception. Brands are increasingly adopting eco-friendly materials in their shrink packaging solutions, which not only reduce their environmental footprint but also cater to the growing consumer demand for sustainable products. According to a report by ResearchAndMarkets, the global eco-friendly packaging market is projected to reach $500 billion by 2027. This shift is largely driven by stricter regulations on plastic usage and an increasing awareness of the benefits of sustainable materials.

One of the most promising innovations in this realm is the development of bioplastics, which are derived from renewable sources such as cornstarch and sugarcane. These materials offer the same durability and functionality as traditional plastics while being biodegradable. The Market Research Future report indicates that the biodegradable packaging segment is expected to grow at a CAGR of 12% from 2021 to 2027. This growth reflects not only the demand for more responsible packaging solutions but also showcases advancements in production technology that make bioplastics more accessible and cost-effective for manufacturers. As we move into 2024, the integration of sustainable materials in shrink packaging will undoubtedly play a crucial role in meeting both regulatory requirements and consumer expectations.

One of the most promising innovations in this realm is the development of bioplastics, which are derived from renewable sources such as cornstarch and sugarcane. These materials offer the same durability and functionality as traditional plastics while being biodegradable. The Market Research Future report indicates that the biodegradable packaging segment is expected to grow at a CAGR of 12% from 2021 to 2027. This growth reflects not only the demand for more responsible packaging solutions but also showcases advancements in production technology that make bioplastics more accessible and cost-effective for manufacturers. As we move into 2024, the integration of sustainable materials in shrink packaging will undoubtedly play a crucial role in meeting both regulatory requirements and consumer expectations.

In the evolving landscape of packaging, the integration of smart automation and AI is revolutionizing shrink packing operations. As companies strive for efficiency and reduced production costs, technologies such as machine learning, computer vision, and predictive analysis are becoming essential tools. These advancements not only streamline operations but also enhance quality control and inventory management, ultimately allowing businesses to respond to market demands with greater agility.

A noteworthy example is the comprehensive automation efforts undertaken by a leading global beverage company, which has transformed its operational strategies. By employing AI-driven solutions, it is reshaping product development, optimizing production processes, and improving overall supply chain efficiency. This holistic approach enables the organization to maintain a competitive edge in a fast-paced market. Furthermore, collaborations between packaging machinery providers and robotics firms are leading to innovative demonstrations of integrated bagging solutions, showcasing the potential for seamless human-robot collaboration on the factory floor.

As the packaging industry moves into 2024, embracing these smart technologies will be vital for staying ahead in the market.

As the demand for efficiency in production lines continues to rise, high-speed shrink packing machines are evolving to meet these needs. In 2024, manufacturers are leveraging cutting-edge technologies to enhance throughput without compromising on packaging quality. Innovations such as automatic film feeding and advanced sealing systems are setting new benchmarks for speed and reliability.

Tip: When investing in new equipment, assess your current workflow and identify areas where high-speed solutions could make a significant impact. This analysis ensures that your transition to faster machines aligns with your overall production goals.

Furthermore, the integration of smart automation in shrink packing machines is revolutionizing production processes. With features like real-time monitoring and AI-driven adjustments, these machines optimize performance and reduce downtime. Operators can now focus on managing production as the machines adapt to changing conditions swiftly.

Tip: Ensure your team is adequately trained in operating new high-speed machines. Familiarity with the technology can significantly enhance productivity while minimizing the risk of errors.

In the fast-evolving landscape of packaging technology, user-friendly designs are taking center stage, particularly in shrink packing machines. As businesses strive to enhance operational efficiency, intuitive interfaces have become crucial for streamlining processes. These modern designs minimize the learning curve for operators and reduce the risk of errors, ultimately leading to smoother workflows. The integration of touchscreen controls and simplified navigation allows workers to operate machinery confidently, ensuring that implementation is quick and seamless.

In the fast-evolving landscape of packaging technology, user-friendly designs are taking center stage, particularly in shrink packing machines. As businesses strive to enhance operational efficiency, intuitive interfaces have become crucial for streamlining processes. These modern designs minimize the learning curve for operators and reduce the risk of errors, ultimately leading to smoother workflows. The integration of touchscreen controls and simplified navigation allows workers to operate machinery confidently, ensuring that implementation is quick and seamless.

Moreover, the trend towards user-centric design reflects a larger shift across industries, where technology is increasingly leveraged to enhance user experience. Just as intuitive design tools are emerging in software to streamline user interactions, shrink packing machines are evolving to meet similar demands. These innovations not only improve operational efficiency but also align with broader business strategies aimed at digital transformation and customer-centric approaches, echoing the need for tools that adapt to real-world applications. As we move towards 2024, keeping an eye on these trends will be vital for businesses looking to stay competitive and enhance their operational capabilities.