Heat Shrink Wrap is an indispensable tool across various industries, offering protection, insulation, and a professional finish for numerous applications. According to a report by MarketsandMarkets, the global heat shrinkable materials market is projected to reach $9.5 billion by 2026, growing at a CAGR of 5.5%. This surge underscores the increasing adoption of heat shrink wrap in sectors such as electronics, automotive, and packaging. However, mastering the techniques of applying heat shrink wrap effectively is crucial to maximizing its benefits. Whether you are a seasoned professional or a novice, understanding the essential tips for using heat shrink wrap can greatly enhance the quality and durability of your projects. By exploring these valuable insights, you will learn to navigate the nuances of heat shrink wrap application like a pro, ensuring your work not only meets but exceeds industry standards.

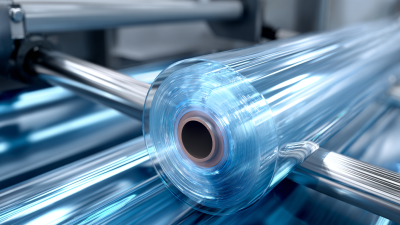

Heat shrink wrap is a versatile material used across various industries, offering protection and insulation for products ranging from electronics to packaging. Understanding the properties of heat shrink wrap materials is essential for effectively employing these techniques. The most common types include polyolefin, PVC, and polyethylene, each with unique characteristics suited for specific applications. Polyolefin is popular for its durability and clarity, making it ideal for retail packaging. PVC, while economical and easy to work with, is best suited for items requiring sturdy protection, while polyethylene provides excellent moisture barriers for food products.

To master heat shrink wrap techniques like a pro, consider these essential tips. First, always preheat your heat gun to the right temperature to ensure even shrinking without damaging the wrap. Second, use the appropriate size of wrap for your item to avoid excess material, which can complicate the process. Lastly, practice patience; overlapping areas should be shrunk slowly to avoid trapping air bubbles that can compromise the seal. With a solid understanding of the material types and these handy tips, you can elevate your heat shrink wrapping skills significantly.

| Type of Heat Shrink Wrap | Common Uses | Temperature Shrinkage Range (°F) | Features |

|---|---|---|---|

| Polyolefin | Electronics, wires, and cables | 250°F - 300°F | Flexible, durable, and low odor |

| PVC | Industrial applications, bundle packaging | 200°F - 250°F | Cost-effective and versatile |

| Kynar | Wire insulation and protection in harsh environments | 300°F - 350°F | Chemical resistant and high temperature stability |

| Polyethylene | Lawn and garden equipment, pipe insulation | 150°F - 200°F | Lightweight and moisture resistant |

| FEP (Fluorinated Ethylene Propylene) | Highly demanding electrical applications | 400°F - 500°F | Excellent resistance to high temperatures and chemicals |

When it comes to applying heat shrink wrap efficiently and effectively, having the right tools is essential. Start with a quality heat gun, as it provides the controlled heat necessary to shrink the wrap without damaging the materials underneath. Additionally, a pair of sharp scissors or a utility knife will ensure clean cuts, allowing for precise application. A heat shrink tubing kit can also be invaluable, as it includes various sizes of tubing to accommodate different projects.

Incorporating these tips can elevate your heat shrink wrap technique. Firstly, remember to prep your work area; a clean surface allows for better adhesion and reduces the risk of contamination. Secondly, apply the shrink wrap smoothly to avoid wrinkles, and always work from one end to the other. This helps in achieving a tight fit around your items. Lastly, when using the heat gun, maintain a safe distance and move it in a sweeping motion to evenly distribute heat, preventing burns or uneven shrinking.

Preparing items for optimal heat shrinking results requires attention to detail and proper technique. Start by selecting the right heat shrink wrap material that matches the size and shape of the items to be covered. Measure accurately to ensure that the wrap fits snugly around the object without excessive overlapping or gaps. Clean the surface of the item thoroughly to remove any dirt, grease, or residue, as these can affect the adhesion and shrinkage of the wrap.

Preparing items for optimal heat shrinking results requires attention to detail and proper technique. Start by selecting the right heat shrink wrap material that matches the size and shape of the items to be covered. Measure accurately to ensure that the wrap fits snugly around the object without excessive overlapping or gaps. Clean the surface of the item thoroughly to remove any dirt, grease, or residue, as these can affect the adhesion and shrinkage of the wrap.

Next, position the heat shrink wrap carefully around the item, making sure it is centered and free of wrinkles. A uniform application will help achieve even heat distribution during the shrinking process. If necessary, use tape or clips to secure the wrap in place temporarily. When ready, use a heat gun or shrink wrapping tool, maintaining a consistent distance to prevent overheating any specific area. The goal is to allow the heat to gradually activate the shrinkage, resulting in a tight and professional finish.

When it comes to mastering heat shrink wrap techniques, achieving professional-grade sealing is crucial for protecting and enhancing your projects. To start, preparation is key. Ensure that your items are clean, dry, and free of sharp edges that could puncture the shrink material. Using a heat gun or heat source at a controlled distance will help you avoid overheating, which can lead to damage or uneven sealing. Always test on a scrap piece of shrink wrap to familiarize yourself with the heat application before working on your actual project.

Additionally, utilizing the right shrink wrap material can significantly influence your results. Different types of wrap are designed for specific applications, so select one that aligns with your needs—whether it’s for packaging, insulation, or bundling. Employing a consistent technique when applying heat—moving the heat source back and forth rather than holding it in one spot—ensures an even and effective seal. By mastering these techniques, you can achieve clean, professional-grade results that enhance the durability and appearance of your wrapped items.

Heat shrink wrapping is a valuable technique for packaging and protecting various items, but there are common mistakes that can undermine the effectiveness of the process.

One major error is failing to select the right heat shrink film for the job. Not all films are created equal, and using the incorrect thickness or material can result in inadequate shrinkage or damage to the item.

Be sure to research and choose the appropriate film based on your specific needs.

Another frequent misstep is improper application of heat.

Overheating can lead to burns or holes in the film, while insufficient heat may prevent a proper seal.

To avoid these issues, it’s essential to use a heat gun at the appropriate distance and speed.

A good tip for achieving an even shrink is to work in sections, gradually moving the heat gun around the item to ensure consistent application.

Additionally, neglecting to prepare the item before wrapping can cause problems down the road. Always clean and dry the surface to ensure optimal adhesion.

Take time to properly secure your item and create folds in the film where necessary.

By implementing these tips, you can significantly improve your heat shrink wrapping technique and ensure a professional finish.