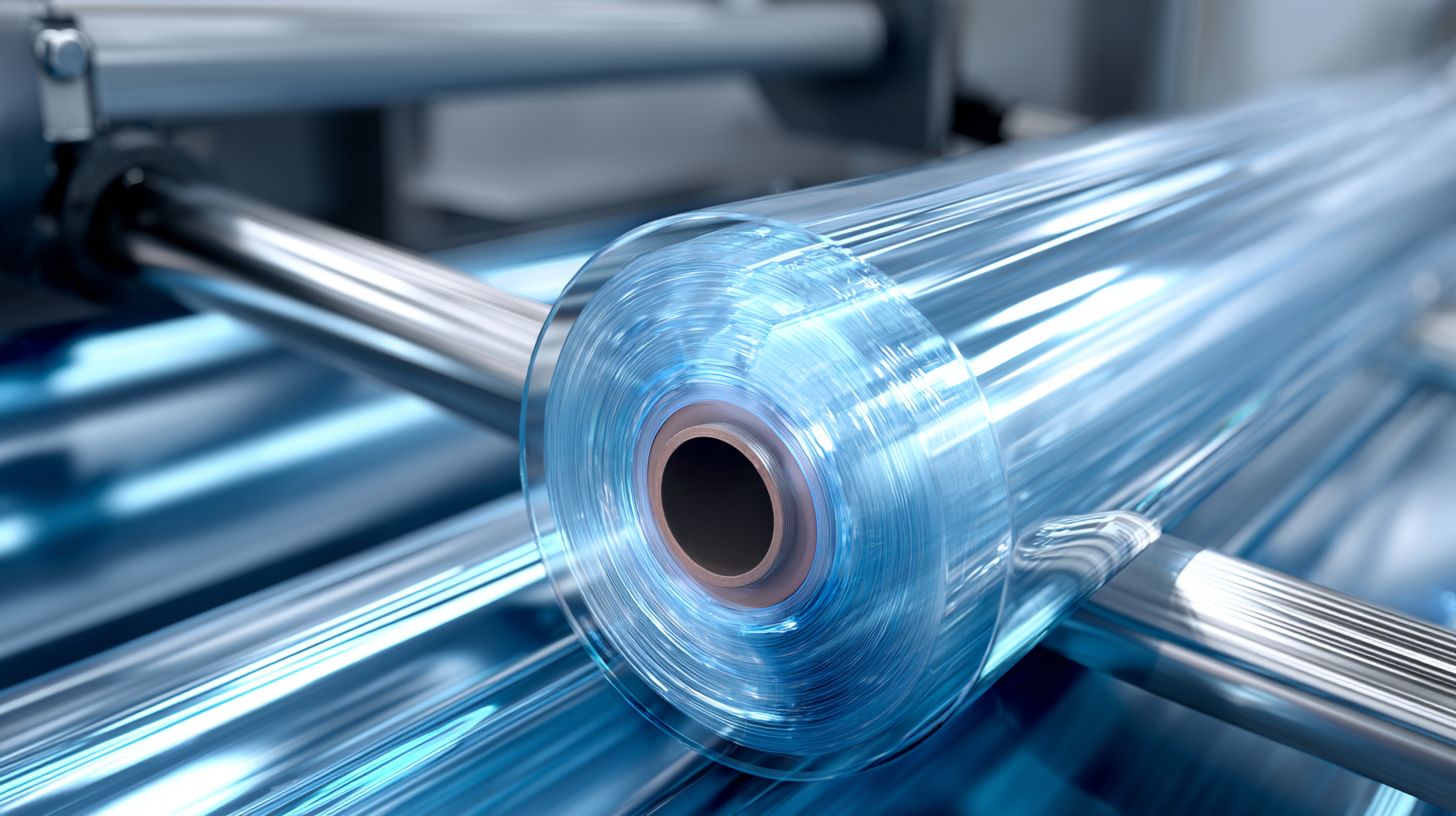

In today's competitive marketplace, ensuring the safety and integrity of products during transportation and storage is paramount. One innovative solution that has gained traction in various industries is Cross-Linked Shrink Film. This specialized packaging material not only offers exceptional strength and durability but also provides a superior barrier against moisture, dust, and contaminants.

As companies strive to optimize their shipping and packaging processes, understanding the benefits of Cross-Linked Shrink Film becomes essential. This comprehensive guide will explore practical strategies to maximize product protection using this advanced shrink film technology.

By delving into key insights and industry data, businesses can make informed decisions that enhance product safety, reduce waste, and ultimately lead to increased customer satisfaction. Whether you're in the food, pharmaceutical, or consumer goods sector, harnessing the potential of Cross-Linked Shrink Film can be a game-changer for your packaging needs.

When selecting cross-linked shrink film for product protection, it's vital to consider several factors that ensure optimal performance. First, evaluate the specific needs of your products, including size, shape, and material sensitivity. Cross-linked shrink films provide superior strength and durability compared to conventional options, making them an ideal choice for safeguarding items during transit and storage. Their ability to conform tightly to various shapes also ensures a secure fit, minimizing the risk of damage from external elements.

Additionally, understanding the environmental conditions your products will face is crucial. For instance, products exposed to high temperatures or humidity can benefit greatly from heat shrink technology. The films are engineered to withstand a range of environmental factors while providing a tight seal. It's important to choose a film that matches the thermal properties necessary for your application, ensuring that it shrinks effectively without compromising the integrity of the product inside. Ultimately, making informed decisions about cross-linked shrink film can significantly enhance product protection across various industries.

Cross-linked shrink film offers significant advantages in product protection, making it an important choice for various industries. This type of shrink film is engineered to provide enhanced durability and resistance to punctures and tears, which is essential for maintaining the integrity of products during storage and transportation. The unique properties of cross-linked films allow for a tighter fit around products, ensuring that they are securely enclosed and less susceptible to environmental damage.

Recent trends in shrink film packaging highlight the growing consumer demand for sustainability and product visibility. As industries pivot towards eco-friendly solutions, cross-linked shrink films can be an excellent option due to their ability to minimize material waste while still providing superior protection. Moreover, their clarity enhances product visibility, making them ideal for retail environments where consumer engagement is vital. The adaptability of heat shrink technology further supports its application across diverse sectors, ranging from food preservation to protective packaging for sterilized medical instruments, showcasing its versatility and efficacy in today's packaging landscape.

When it comes to utilizing cross-linked shrink film for product protection, applying the right techniques is crucial for achieving optimal performance. First, it’s essential to ensure that the film's heat settings are calibrated correctly. Overheating can lead to excessive shrinking, which might compromise the integrity of the package, while insufficient heat can result in inadequate sealing.

**Tips:** Always test the heat settings with a sample package to find the ideal temperature for your specific film and product combination. Use a thermal imaging gun to monitor the heating process, ensuring an even application across surfaces.

Moreover, consider the design of your package. Products with irregular shapes or sharp edges may require additional cushioning to prevent damage during handling and transportation. By strategically placing protective materials within the packing space, you can enhance the effectiveness of the shrink film.

**Tips:** Incorporate padding materials like foam or bubble wrap to support delicate items and reduce movement inside the package. This not only extends the lifespan of your products but also ensures that the shrink film adheres tightly for maximum protection.

| Application Technique | Shrink Film Type | Optimal Temperature (°F) | Film Thickness (microns) | Protection Level |

|---|---|---|---|---|

| Horizontal Forming | Cross-Linked Polyolefin | 400 | 50 | High |

| Vertical Forming | Cross-Linked PVC | 375 | 40 | Medium |

| Bundling | Cross-Linked Polyethylene | 425 | 60 | Very High |

| Single Pack | Cross-Linked PET | 390 | 30 | Medium |

Cross-linked shrink film has emerged as a vital component in improving packaging efficiency across various industries. Reports indicate that the use of cross-linked films can enhance tensile strength by up to 40% compared to traditional polyolefin films. This remarkable increase in durability helps protect products during transit and storage, effectively reducing damage rates by an impressive 30%, as noted in a study conducted by the Flexible Packaging Association (FPA).

Cross-linked shrink film has emerged as a vital component in improving packaging efficiency across various industries. Reports indicate that the use of cross-linked films can enhance tensile strength by up to 40% compared to traditional polyolefin films. This remarkable increase in durability helps protect products during transit and storage, effectively reducing damage rates by an impressive 30%, as noted in a study conducted by the Flexible Packaging Association (FPA).

Moreover, the benefits of cross-linked shrink film extend beyond strength. A recent market analysis highlighted that companies utilizing these films experience a 20% increase in packaging line speed. This efficiency boost is attributed to the films’ superior shrinking properties, which allow for faster application and sealing processes. Consequently, businesses not only achieve greater protection for their products but also realize significant labor cost savings and improved throughput. These insights emphasize the critical role that cross-linked shrink film plays in optimizing packaging solutions while minimizing waste and maximizing product integrity.

When considering product protection in packaging, cross-linked shrink film stands out as a superior option compared to traditional materials like polyethylene or polypropylene. The unique properties of cross-linked films, such as enhanced strength and durability, make them particularly effective in safeguarding items from damage during transit and storage. Unlike standard shrink films, which can easily tear or puncture, cross-linked films exhibit resistance to harsh conditions, offering better impact protection and a more secure seal around products.

Moreover, the heat resistance of cross-linked shrink films ensures they maintain their integrity under varying temperature conditions. This characteristic is especially beneficial in industries that require products to be stored or shipped in environments with fluctuating temperatures. In comparison, conventional packing materials may suffer from deformation or further fragility when subjected to heat. By integrating cross-linked shrink film into your packaging strategy, businesses can achieve not only improved protection for their products but also an enhanced presentation that can attract customers and enhance brand perception.