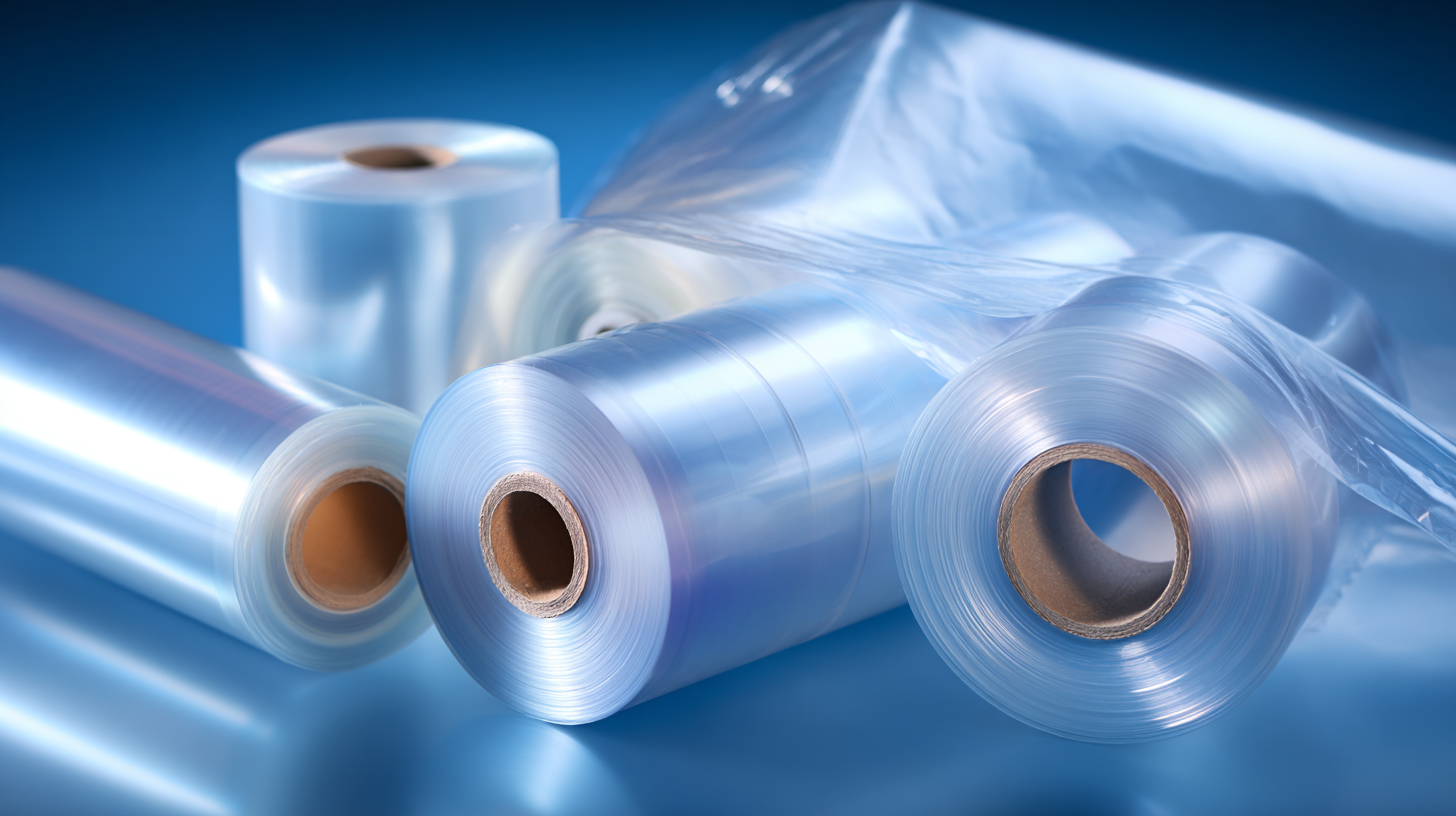

In today’s fast-paced business environment, the efficiency of packaging solutions can significantly impact a company’s operational success and bottom line. Among various options available, Plastic Shrink Packaging stands out as a versatile and effective choice for a multitude of industries. This form of packaging not only ensures the safety and integrity of products during transit but also enhances shelf appeal and can contribute to overall cost savings. However, to fully harness the potential of Plastic Shrink Packaging, finding a high-quality supplier is crucial. The right partner can provide innovative solutions tailored to specific needs while maintaining high standards of quality and sustainability.

In this blog, we will explore top strategies to maximize efficiency through the selection of the best Plastic Shrink Packaging suppliers, highlighting key attributes to consider and best practices for fostering successful supplier relationships.

Innovative materials are at the forefront of enhancing efficiency in plastic shrink packaging. Advanced polymer technologies have revolutionized the way products are packaged, ensuring they are both secure and visually appealing. By utilizing high-performance polyolefins, manufacturers can create thinner films that provide the same strength and protection as their thicker counterparts, leading to significant material savings and reduced waste.

Tip: Consider investing in biodegradable shrink films. These sustainable alternatives not only align with growing consumer demand for eco-friendly packaging but also maintain the necessary performance levels for effective product protection.

Moreover, the introduction of multi-layer films has improved barrier properties, allowing products to have extended shelf lives while minimizing spoilage. This is particularly beneficial for perishable goods, which require robust packaging solutions to withstand the rigors of transportation and storage.

Tip: When selecting shrink packaging materials, prioritize those with enhanced thermal properties to optimize the shrinking process. This can lead to faster packing times and higher throughput, ultimately boosting overall operational efficiency.

| Strategy | Material Type | Efficiency Gain (%) | Application |

|---|---|---|---|

| High-Speed Shrink Wrapping | PVC (Polyvinyl Chloride) | 30% | Food Packaging |

| Sustainable Packaging Solutions | PLA (Polylactic Acid) | 25% | Consumer Goods |

| Multi-layer Films | POF (Polyolefin) | 20% | Pharmaceuticals |

| Automated Shrink-Sleeve Application | PETG (Polyethylene Terephthalate Glycol) | 15% | Beverage Packaging |

| Advanced Heat Tunnel Technologies | RPET (Recycled PET) | 18% | Personal Care Products |

Efficiency in production processes is crucial for businesses aiming to enhance their packaging solutions. By streamlining production, companies can not only reduce costs but also improve product presentation and customer satisfaction. One effective approach is to integrate advanced technology in the shrink wrapping process.

Automated machinery helps in achieving consistent wrap quality and reduces handling time, allowing for faster turnaround.

Automated machinery helps in achieving consistent wrap quality and reduces handling time, allowing for faster turnaround.

Additionally, optimizing material selection plays a significant role in efficiency. Using high-quality plastic shrink films specifically designed for automation can minimize waste and enhance the durability of the packaging. This ensures that products are securely wrapped while reducing the need for excess material, thus contributing to sustainability efforts. Implementing comprehensive training for staff on these new systems and materials is also essential, as it ensures that everyone is proficient in utilizing the available technologies, further streamlining the production workflow.

Incorporating feedback loops within the production team is another key strategy. By regularly assessing packaging effectiveness and gathering insights from the employees involved in the process, companies can identify bottlenecks and areas for improvement. This proactive approach facilitates continuous enhancement of packaging strategies, ultimately leading to a more efficient production environment and better service to customers.

The plastic shrink packaging industry is undergoing a significant transformation towards sustainable practices, driven by consumer demand and regulatory changes. According to a report by Smithers Pira, the global market for sustainable packaging is expected to reach $400 billion by 2027, with plastic shrink solutions playing a pivotal role in this shift. Companies are increasingly adopting bio-based and recycled materials for their shrink films, which significantly reduce their environmental footprint. For instance, a recent study revealed that using post-consumer recycled (PCR) materials can decrease carbon emissions by up to 30%, making it a viable alternative to traditional plastic sources.

Moreover, innovations in shrink packaging technology are enabling manufacturers to enhance their sustainability efforts. Advanced machinery and processes now allow for thinner, more efficient packaging that requires less material without sacrificing performance. According to research by the Flexible Packaging Association, optimized shrink packaging can cut down material usage by approximately 20%, while still providing robust protection for products. These changes not only improve the overall efficiency of packaging operations but also resonate with eco-conscious consumers who are increasingly prioritizing environmentally-friendly products. As such, the focus on sustainability in the plastic shrink packaging industry is both a response to market trends and a crucial step towards a more sustainable future.

When it comes to plastic shrink packaging, cost-effectiveness is a primary concern for businesses aiming to optimize their operations. According to a recent report by Smithers Pira, the global market for shrink packaging is expected to reach $29.8 billion by 2027, indicating a robust demand driven by its ability to provide secure and appealing product presentation at a lower cost compared to other packaging solutions. Companies can significantly reduce material waste by utilizing lightweight and durable shrink films, which leads to lower shipping costs and enhanced sustainability.

Moreover, advancements in manufacturing processes have allowed for high-quality shrink films that do not compromise performance. Research from the Packaging Association shows that using high-performance shrink films can result in up to 40% savings in material use while maintaining the strength and integrity necessary to protect products during transit. By strategically selecting shrink packaging solutions that emphasize cost-effectiveness without sacrificing quality, businesses can improve their overall efficiency while achieving a higher return on investment.

The global market for plastic shrink packaging is witnessing significant shifts, driven by advancements in technology and changing consumer preferences. Manufacturers are increasingly seeking efficient packaging solutions that not only enhance product protection but also offer sustainability benefits. The use of biodegradable materials and recyclable shrink films has become a focal point, as companies aim to align with the growing demand for environmentally friendly packaging options. This trend not only caters to consumer expectations but also helps manufacturers comply with stringent regulations regarding packaging waste.

In addition to sustainability, the rise of e-commerce is reshaping the plastic shrink packaging landscape. With online shopping on the rise, the need for packaging solutions that ensure product safety during transit has intensified. Strategic innovations, such as enhanced sealing techniques and custom-fit shrink wraps, are essential for minimizing damage and ensuring that products reach consumers in pristine condition. As manufacturers adapt to these global market trends, investing in the latest shrink packaging technologies proves crucial for maximizing efficiency and maintaining a competitive edge in an increasingly dynamic marketplace.