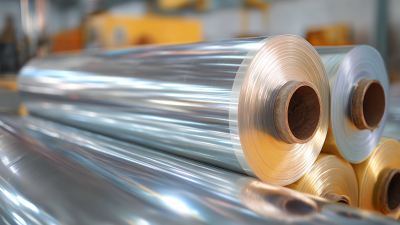

In today's competitive logistics landscape, optimizing shipping processes is essential for businesses aiming to reduce costs and improve efficiency. A crucial technique that has gained attention is Shrink And Wrap, which not only secures products but also enhances their protection during transit. According to a recent report from the Packaging Association, companies utilizing shrink wrap techniques have reported a reduction in shipping damage by up to 30%, showcasing its effectiveness in safeguarding merchandise.

Moreover, the global shrink film market is projected to reach $7.9 billion by 2025, as more industries recognize the economic benefits and environmental sustainability offered by advanced packaging solutions. By adopting these innovative methods, businesses can streamline their operations, minimize waste, and ultimately enhance customer satisfaction.

When it comes to optimizing your shipping process, effective shrink and wrap techniques play a vital role. These methods not only protect products during transit but also enhance their presentation. Implementing these strategies can lead to reduced damage, lower shipping costs, and increased efficiency in your operations.

One essential tip is to ensure that the wrapping material is appropriate for the item being shipped. For fragile items, consider using thicker, multi-layer shrink wrap to provide added cushioning. Additionally, make sure to use a heat gun properly to achieve a tight seal, which prevents shifting during transportation. This thoughtful approach to packaging not only safeguards your products but also strengthens your brand’s image through professional presentation.

Another effective strategy is to maximize space during the wrapping process. Group smaller items together and wrap them as a single unit to save space and reduce shipping costs. Use dunnage or air pillows to fill any voids within the wrap, ensuring that the items remain secured. By adopting these techniques, your shipping operations will become more streamlined, efficient, and ultimately more cost-effective.

Proper wrapping techniques play a pivotal role in minimizing shipping damage rates. According to a report by the National Association of Manufacturers, about 58% of damage costs in shipping are attributable to inadequate packaging. When products are not wrapped securely, they are more susceptible to impacts and environmental factors during transit, leading to increased returns and customer dissatisfaction. Implementing shrink and wrap methods can significantly enhance protection, reducing the likelihood of damage in transit.

Tips for effective wrapping include choosing the right materials that provide cushioning—such as bubble wrap or foam inserts—along with using high-quality shrink film to secure the package. Additionally, consider double-wrapping fragile items to add an extra layer of protection. A study by Packaging Digest reveals that properly wrapped products can reduce damage rates by up to 30%, translating to substantial savings on replacement costs and improving overall customer experience.

Another vital tip is to ensure that packages are tightly sealed to prevent movement during shipping. According to the international shipping standards, over 40% of product failures are linked to inadequate sealing. Investing in reliable shrink and wrap techniques can yield significant benefits, both in safeguarding merchandise and enhancing operational efficiency within the shipping process.

| Shipping Method | Wrapping Technique | Damage Rate (%) | Shipping Time (Days) | Customer Satisfaction Rating (out of 10) |

|---|---|---|---|---|

| Standard Shipping | Shrink Wrap | 2.5 | 5 | 8.5 |

| Express Shipping | Bubble Wrap | 1.2 | 3 | 9.2 |

| Economy Shipping | Paper Packing | 4.0 | 7 | 7.0 |

| Priority Shipping | Double Layer Shrink Wrap | 0.8 | 2 | 9.5 |

| Freight Shipping | Strapping and Shrink Film | 3.5 | 10 | 8.0 |

Shrink wrapping has gained traction in various industries as a cost-effective solution for packaging and shipping. According to a report by Smithers Pira, the global flexible packaging market is expected to grow to $290 billion by 2027, driven by methodologies such as shrink wrapping that offer efficiency and protection. When businesses implement shrink wrapping, they often see a reduction in packaging costs by as much as 25%, significantly impacting their bottom line.

Moreover, shrink wrapping minimizes material waste, an essential factor in today's environmentally conscious market. A study by the Flexible Packaging Association highlights that companies using shrink wrap can save up to 40% in material usage compared to traditional packaging methods. This not only decreases direct costs but also contributes to sustainability efforts by reducing the carbon footprint associated with packaging production and disposal. By optimizing the shipping process through shrink wrapping techniques, businesses can achieve substantial economic and environmental benefits, making it a smart investment for companies aiming to enhance their operational efficiency.

In today's fast-paced logistics environment, integrating technology into your shrink and wrap processes can significantly enhance efficiency and reduce shipping costs. By utilizing automated wrapping machines equipped with advanced sensors, businesses can ensure consistent packaging quality while minimizing the risk of human error. These machines can adjust wrap tension and film usage based on the product size, leading to optimal material utilization and lower overhead.

Tips for optimizing your wrapping process include investing in real-time tracking technology to monitor shipment conditions and prevent damage. This allows you to respond quickly to any issues that may arise during transit. Additionally, consider implementing a comprehensive inventory management system that syncs with your wrapping technology. This integration not only streamlines workflow but also provides insights into shipping patterns and helps forecast demand accurately.

By adopting these technological enhancements, companies can streamline their shipping operations, ensuring products arrive intact and on time. This proactive approach to shrink wrapping not only saves time but also fosters customer satisfaction and loyalty in the long run.

Training staff on shrink and wrap methods is essential for optimizing the shipping process in warehouses. Effective training not only ensures that the employees are proficient in these techniques but also promotes safety and efficiency in day-to-day operations. Incorporating ergonomic solutions during training can minimize the risk of musculoskeletal disorders (MSDs) among workers, leading to a healthier workforce. As employees learn to handle materials correctly and efficiently, they are able to perform shrink wrapping tasks with minimal strain, which enhances productivity.

Additionally, implementing green practices while training can contribute to sustainability goals within the warehouse environment. Teaching staff about environmentally friendly materials for shrink wrapping and the importance of reducing waste can foster a culture of responsibility. Emphasizing the benefits of using recyclable shrink films and energy-efficient equipment can further empower employees to make conscientious choices that align with the company’s sustainability objectives. By combining effective staff training with a focus on safety and environmental responsibility, warehouses can optimize their shipping processes while creating a positive work environment.