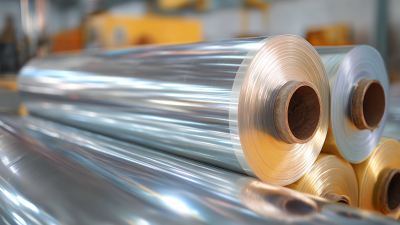

In the fast-paced world of global supply chains, optimizing operational efficiency is paramount for businesses aiming to maintain a competitive edge. One crucial aspect often overlooked is the process of Shrink And Wrap, which directly impacts both cost and product integrity during transportation. Effective Shrink And Wrap practices not only minimize product damage and loss but also streamline packing processes, ensuring that goods are securely prepared for their journey across borders. As companies navigate the complexities of logistics, implementing best practices in Shrink And Wrap can lead to significant improvements in efficiency, reduce waste, and enhance overall supply chain performance. This blog will explore five essential strategies to optimize Shrink And Wrap processes, helping organizations achieve superior results while meeting the ever-growing demands of the global market.

Shrink and wrap techniques play a pivotal role in enhancing supply chain efficiency, especially in the global marketplace where competition is fierce and logistics complexity is ever-growing. By effectively utilizing shrink and wrap, companies can protect their products during transit, reduce damage rates, and ultimately maintain the integrity of their goods. This has a cascading effect on overall supply chain operations, leading to reduced costs associated with returns and replacements, and improving customer satisfaction by ensuring timely and safe deliveries.

In addition to safeguarding products, the use of shrink and wrap can streamline warehouse operations. When products are bundled together efficiently, it cuts down on the space needed for storage and speeds up the loading and unloading processes. This efficiency not only enhances labor productivity but also optimizes inventory management. The careful application of shrink and wrap techniques helps businesses manage their stock levels more accurately, thereby reducing waste and improving resource allocation across the supply chain. As organizations continue to seek ways to thrive in a competitive landscape, understanding and leveraging the role of shrink and wrap becomes essential to achieving operational excellence.

In the ever-evolving landscape of global supply chains, there are critical metrics that businesses must track to optimize shrink and wrap performance effectively. These metrics not only help in assessing the efficiency of operations but also contribute to minimizing waste and enhancing sustainability initiatives. For instance, measuring the rate of shrinkage over time can provide insight into the effectiveness of shrink-wrap procedures, guiding improvements where necessary.

To further enhance performance, companies should adopt best practices such as regular audits of shrink and wrap processes. By implementing checklists and assessing the quality of materials used, organizations can ensure that every layer of protection is optimal, thus reducing the risk of damage during transit. Additionally, leveraging technology like real-time feedback systems can enable teams to quickly identify and resolve inefficiencies, thereby improving overall productivity.

Moreover, integrating metrics for evaluating the multi-dimensional value of recovered resources is vital. Businesses should not only focus on financial metrics but also consider social and environmental implications in their evaluations. This holistic approach will pave the way for more informed decision-making that aligns with the sustainable practices required in today's circular economy.

In the ever-evolving landscape of global supply chains, optimizing shrink and wrap processes has become crucial for enhancing efficiency and reducing costs. Innovative technologies are at the forefront of this transformation, offering solutions that streamline operations and improve overall output. Automation, for example, plays a pivotal role in the shrink wrap process, reducing labor costs while increasing accuracy and speed. Automated shrink wrapping machines not only ensure consistent application of materials but also detect packaging errors in real-time, leading to significant reductions in waste.

Additionally, the incorporation of IoT (Internet of Things) devices within the supply chain enables real-time monitoring of shrink and wrap activities. By leveraging connected sensors, businesses can track product conditions, adjust machinery settings, and predict maintenance needs before downtime occurs. This proactive approach not only enhances the efficiency of shrink and wrap operations but also contributes to improved product integrity throughout the supply chain. As companies continue to embrace these innovative technologies, the potential for enhanced performance in shrink and wrap processes will only grow, setting the stage for a more efficient and responsive global supply chain.

In the realm of global supply chains, selecting the right materials for shrink and wrap can significantly enhance efficiency while also promoting sustainability. According to a report from Smithers Pira, the global market for flexible packaging is forecasted to reach $300 billion by 2025. This growth underscores the need for innovative material choices, like recycled polyethylene and bioplastics, which not only reduce environmental impact but also meet consumer demand for sustainable products.

Furthermore, the importance of sourcing materials with low carbon footprints cannot be overstated. A study published by the Ellen MacArthur Foundation indicates that switching to circular economy models in packaging could save companies up to $700 billion annually by 2030. Implementing best practices such as eco-design and sustainable sourcing strategies will not only enhance operational efficiency but also position brands favorably in an increasingly eco-conscious market. By focusing on these practices, companies can drive significant improvements in shrink and wrap efficiency while contributing to the sustainability goals of their supply chains.

In today's competitive landscape, the efficiency of shrink and wrap processes in global supply chains is paramount. The key to achieving this efficiency lies in investing in training and collaboration among workforce members. Empowering employees with the right skills and knowledge not only enhances their confidence but also leads to more effective operations. By developing comprehensive training programs that cover best practices in shrink wrap techniques, safety protocols, and equipment use, companies can ensure that their teams are equipped to perform at their best.

Furthermore, fostering a culture of collaboration within the workforce enhances communication and problem-solving capabilities. When team members feel supported and encouraged to share ideas, they can identify bottlenecks and suggest improvements in real time. Establishing cross-functional teams that include personnel from logistics, operations, and quality control can also create a more unified approach to optimizing processes. By emphasizing collaboration, organizations can leverage diverse perspectives to drive innovation and efficiency in shrink and wrap operations, leading to significant gains in overall supply chain performance.