In the ever-evolving landscape of packaging solutions, Shrink Film has emerged as a game-changer, providing a multitude of benefits that enhance product protection and presentation. According to a report by Smithers Pira, the global market for shrink film is projected to grow at a CAGR of 4.3% through 2025, reaching approximately $8.5 billion. This impressive growth underscores the increasing adoption of shrink film across various industries, including food and beverage, pharmaceuticals, and consumer goods. Shrink Film not only offers durability and strength but also enhances aesthetic appeal and brand visibility. As companies strive for greater efficiency and sustainability, understanding the proven benefits of using Shrink Film can empower businesses to make informed decisions that align with modern packaging standards, driving both operational excellence and consumer satisfaction. In this blog, we will explore 15 proven benefits of using Shrink Film in contemporary packaging solutions, illustrating why it remains a crucial component in the packaging arsenal.

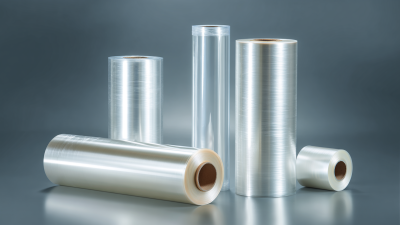

Shrink film is a versatile packaging material that has gained popularity in various industries due to its flexibility and protective qualities. It is made from polymer materials that shrink tightly around the item it covers when heat is applied. This unique characteristic forms a secure, tamper-evident seal that not only protects products but also enhances their presentation. The clarity of shrink film allows consumers to see the product, increasing its appeal on store shelves while providing essential barrier properties against moisture, dust, and contaminants.

One of the significant benefits of shrink film is its adaptability in design and application. It can be customized to fit an array of product shapes and sizes, making it suitable for packaging everything from food items to electronics. Additionally, shrink film is available in various thicknesses and finishes, catering to different market needs. Its lightweight nature also helps reduce shipping costs, making it a cost-effective solution for businesses. As companies continue to seek sustainable packaging options, many shrink films are now available in recyclable and biodegradable forms, ensuring that they meet modern environmental standards while still providing robust performance.

Shrink film has become an indispensable tool in modern packaging solutions, offering a variety of key advantages for various industries. One of the most notable benefits is its superior ability to conform tightly around products. When heat is applied, shrink film shrinks to fit the shape of the item, providing a secure and protective layer that minimizes movement and reduces the risk of damage during transportation. This snug fit not only protects the products but also enhances their presentation, making them more appealing to consumers.

Moreover, shrink film is versatile and can be employed in numerous packaging applications, from retail items to industrial components. Its transparent nature allows for high visibility, promoting brand recognition while providing excellent protection against dust, moisture, and tampering. Additionally, the lightweight properties of shrink film contribute to cost savings on shipping and storage, as they take up minimal space compared to traditional packaging materials. These advantages make shrink film an optimal choice for businesses seeking efficiency and sustainability in their packaging processes.

Shrink film is increasingly recognized for its role in promoting sustainable packaging solutions. According to a report by the Flexible Packaging Association, the use of shrink film can reduce material waste significantly when compared to traditional packaging options. This is largely due to its lightweight nature, which minimizes the energy consumption during transportation. Research shows that lightweight packaging can lead to a 60% reduction in greenhouse gas emissions per shipment, addressing the urgent challenges of climate change.

Shrink film is increasingly recognized for its role in promoting sustainable packaging solutions. According to a report by the Flexible Packaging Association, the use of shrink film can reduce material waste significantly when compared to traditional packaging options. This is largely due to its lightweight nature, which minimizes the energy consumption during transportation. Research shows that lightweight packaging can lead to a 60% reduction in greenhouse gas emissions per shipment, addressing the urgent challenges of climate change.

Furthermore, many shrink films are now made from recyclable materials. The Sustainable Packaging Coalition indicates that as much as 40% of shrink film products can be recycled, contributing to a circular economy. This not only helps in reducing landfill waste but also encourages the use of renewable resources. As the consumer preference shifts toward eco-friendly products, companies adopting shrink film solutions can align with these values while also meeting regulatory demands for sustainability. By integrating shrink film into their packaging practices, businesses can make substantial strides toward environmental responsibility while enhancing their operational efficiency.

In today's rapidly evolving packaging industry, shrink film has emerged as a versatile solution utilized across various sectors. The global shrink packaging market is projected to grow significantly, with its size expected to reach approximately USD 21.55 billion by 2034, up from USD 11.73 billion in 2024. This surge highlights the increasing adoption of shrink film for its efficiency, cost-effectiveness, and ability to enhance product aesthetics and shelf life.

Innovations in shrink film technology are also shaping its application landscape. Recent launches include high-performance and opaque polyolefin shrink films, designed for specific labeling needs, showcasing the adaptability of shrink film in meeting diverse market demands. Furthermore, partnerships aimed at developing biodegradable shrink films reflect the industry’s commitment to sustainability, driven by consumer preferences for environmentally friendly packaging. As companies seek to stay competitive, embracing shrink film solutions can provide significant advantages in both operational efficiency and consumer appeal.

Shrink film has gained significant traction in modern packaging solutions due to its multitude of advantages over traditional methods. One of the primary benefits is the enhanced protection it offers. Unlike cardboard or other rigid packaging, shrink film conforms to the shape of the product, providing a snug and secure fit that minimizes movement during transit and prevents damage. This tight wrapping not only safeguards items from external elements like moisture and dust but also reduces the risk of accidental breakage or spoilage, an essential factor for companies shipping fragile goods.

Moreover, shrink film is often more cost-effective than traditional packaging materials. Traditional methods often require multiple packaging components, such as boxes, protective cushioning, and tape, each contributing to higher costs. In contrast, shrink film typically requires fewer materials, streamlining the packaging process and saving on production costs. Additionally, its lightweight nature can lead to reduced shipping expenses. Businesses can also benefit from the space-saving qualities of shrink film, as it allows for more efficient storage and transportation, maximizing the use of available space during shipping. This comparative efficiency makes shrink film an optimal choice for modern packaging needs.

| Benefit | Shrink Film | Traditional Packaging |

|---|---|---|

| Cost-effectiveness | Lower material costs, less waste | Higher material costs, more waste |

| Product visibility | Clear films enhance product display | Limited visibility with opaque materials |

| Durability | Resistant to tears and punctures | Can be less durable in handling |

| Customization | Easily printable with designs | More limited design options |

| Sealing | Provides an airtight seal | May not offer airtight options |

| Lightweight | Reduces shipping costs | Generally heavier materials |

| Environmental impact | Recyclable options available | Limited recyclable materials |

| Versatility | Suitable for a variety of products | Less adaptable to product changes |

| Tamper evidence | Indicates product tampering | Harder to detect tampering |

| Shrink conformity | Forms tightly around products | May not conform well to irregular items |

| Shelf life | Increases shelf life by reducing moisture | Limited moisture protection |

| Speed of production | Faster application and sealing | Slower packaging processes |

| Safety | Ease of handling and reduced breakage | Higher risk of product damage |