Shrink Film Packaging has revolutionized the way products are protected and presented in various industries. According to a report by Smithers Pira, the global market for shrink film is projected to reach approximately $10 billion by 2024, demonstrating its increasing significance in the packaging sector. This innovative packaging solution not only enhances the visual appeal of products but also provides essential protection against environmental factors, damage, and tampering. The science behind Shrink Film Packaging involves the application of heat to create a tight, protective seal around products, which helps in maintaining their integrity and freshness. Additionally, the versatility of shrink films—ranging from PVC to polyolefin—caters to various market requirements while contributing to sustainability efforts. As companies continue to recognize the impact of high-quality packaging on consumer experience and brand perception, Shrink Film Packaging is poised to play a pivotal role in optimizing product protection and enhancing shelf life.

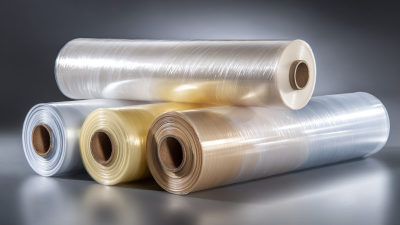

Shrink film is a versatile packaging material composed primarily of polymer-based plastics, such as polyolefin or PVC. These films are designed to shrink tightly around products when heat is applied, creating a protective layer that enhances aesthetics and security. The composition of shrink film includes additives that improve clarity, strength, and resistance to environmental factors, making it suitable for various applications ranging from food to industrial goods. Polyolefin shrink films, for instance, are known for their superior stretchability and seal strength, while PVC films offer excellent conformability for irregularly shaped items.

The properties of shrink film are equally crucial in determining its effectiveness. The shrinkage rate—typically ranging from 30% to 70%—is a key consideration, as it dictates how tightly the film will conform to the product. Additionally, shrink films possess excellent shrink memory, allowing them to recover their original shape after being heated. This property not only facilitates easy application but also ensures that the packaging maintains a snug fit over the item, providing optimal protection against dust, moisture, and mechanical damage. Understanding these components and properties is essential for selecting the appropriate shrink film for specific packaging needs, ultimately enhancing product protection and presentation.

Shrink film packaging is an innovative technique widely used in various industries for its effectiveness in protecting products. The application process involves several key techniques and equipment designed to ensure thorough coverage and a secure fit. Initially, products are wrapped with a tubular shrink film, which can come in various sizes and thicknesses, depending on the item being packaged. Once the product is wrapped, heat is applied using heat guns or shrink tunnels, which allows the film to contract and tightly conform to the shape of the product, providing an airtight seal that protects against dust, moisture, and tampering.

Shrink film packaging is an innovative technique widely used in various industries for its effectiveness in protecting products. The application process involves several key techniques and equipment designed to ensure thorough coverage and a secure fit. Initially, products are wrapped with a tubular shrink film, which can come in various sizes and thicknesses, depending on the item being packaged. Once the product is wrapped, heat is applied using heat guns or shrink tunnels, which allows the film to contract and tightly conform to the shape of the product, providing an airtight seal that protects against dust, moisture, and tampering.

Tips: When selecting shrink film, consider the size and weight of your product to ensure optimal performance. Additionally, ensure that your heat source is often calibrated for consistent application to prevent over or under-heating the film.

Moreover, modern shrink wrapping machinery has advanced significantly, introducing automation to streamline the process. Automatic sleeve sealers and shrink tunnels enhance speed and efficiency, making it easier for businesses to package large quantities at once. Investing in quality equipment can lead to better results as well as reduced labor costs.

Tips: Regular maintenance of your shrink wrapping equipment can significantly prolong its lifespan and maintain packaging quality. Always follow the manufacturer's guidelines for optimal results.

Shrink film packaging has emerged as a crucial element in safeguarding products across various industries. With benefits such as enhanced barrier protection and cost-efficiency, its impact on product integrity is significant. According to a report by Smithers Pira, the global shrink film market was valued at approximately $3.5 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 4.8% through 2026. This growth underscores the increasing reliance on shrink film for its protective qualities.

One of the key advantages of shrink film packaging is its ability to conform tightly to the product, minimizing movement during transit and storage. This snug fit not only prevents physical damage but also reduces the risk of contamination. A study conducted by the Flexible Packaging Association indicated that over 85% of respondents acknowledged shrink film as an effective means of preventing spoilage and damage. Moreover, shrink film's resistance to moisture and UV light further extends product shelf life, reinforcing its role in product protection.

Sustainability has emerged as a crucial aspect of shrink film packaging, prompting manufacturers to innovate and adopt eco-friendly materials. Traditional shrink films often rely on non-biodegradable plastics that contribute to environmental pollution. In response, companies are now exploring bio-based options made from renewable resources, such as plant starch or polylactic acid (PLA). These biodegradable materials not only reduce the ecological footprint but also fulfill consumer demands for greener packaging solutions.

Moreover, advances in recycling technologies and circular economy practices are enhancing the sustainability of shrink film packaging. Many manufacturers are implementing closed-loop systems, ensuring that used shrink films can be collected, processed, and reused in new packaging products. The introduction of recyclable shrink films helps minimize waste while maintaining product integrity and protection. Through these innovations, the shrink film packaging industry is making significant strides towards sustainability, aligning with global efforts to reduce plastic waste and promote environmentally responsible practices.

| Aspect | Details |

|---|---|

| Material Types | PVC, PE, PETG, PLA |

| Key Benefits | Tamper evidence, protection from moisture, enhanced shelf life |

| Sustainability Features | Biodegradable options, recyclable materials, reduced plastic usage |

| Innovations in Technology | Advanced film technologies, improved shrink ratios, clearer films |

| Applications | Food packaging, consumer goods, electronics |

| Environmental Impact | Lower carbon footprint compared to traditional packaging methods |

Shrink film packaging plays a pivotal role across various industries, protecting products while enhancing aesthetic appeal. The food and beverage sector extensively utilizes shrink films to ensure product safety and prolong shelf life. According to a report by MarketsandMarkets, the global shrink film market is projected to grow from $6.91 billion in 2021 to $10.95 billion by 2026, showcasing the increasing demand for efficient packaging solutions in food preservation. The films effectively provide tamper evidence and moisture protection, which are critical in maintaining the quality of consumables.

In addition to food packaging, shrink films are widely used in the pharmaceutical industry. A study by Grand View Research indicates that the pharmaceutical packaging market is expected to reach $1.1 trillion by 2027, with shrink films playing a vital role in ensuring that medicines remain secure and effective. These films help in maintaining hygiene and safety by offering a barrier against contaminants. Moreover, in the consumer goods sector, shrink films are favored for bundling multiple products, which not only reduces packaging waste but also enhances shipping efficiency. This versatility confirms that shrink film packaging is essential for a wide range of applications, maximizing product protection and consumer satisfaction.