In today’s fast-paced manufacturing landscape, the need for efficiency and innovation is more critical than ever, and one of the most transformative solutions lies in the realm of Shrink Packaging Machine technology. These machines not only streamline the packaging process but also enhance product protection and presentation, ultimately contributing to increased productivity and cost savings. As companies seek to optimize their operations, understanding the various types of shrink packaging machines available and their unique features becomes essential. This article will explore the advantages of adopting innovative shrink packaging machine technology, highlighting how it can revolutionize a packaging line and improve overall operational efficiency. By embracing these advancements, businesses can ensure they remain competitive in a rapidly evolving marketplace while meeting the growing demands of consumers for high-quality, well-packaged products.

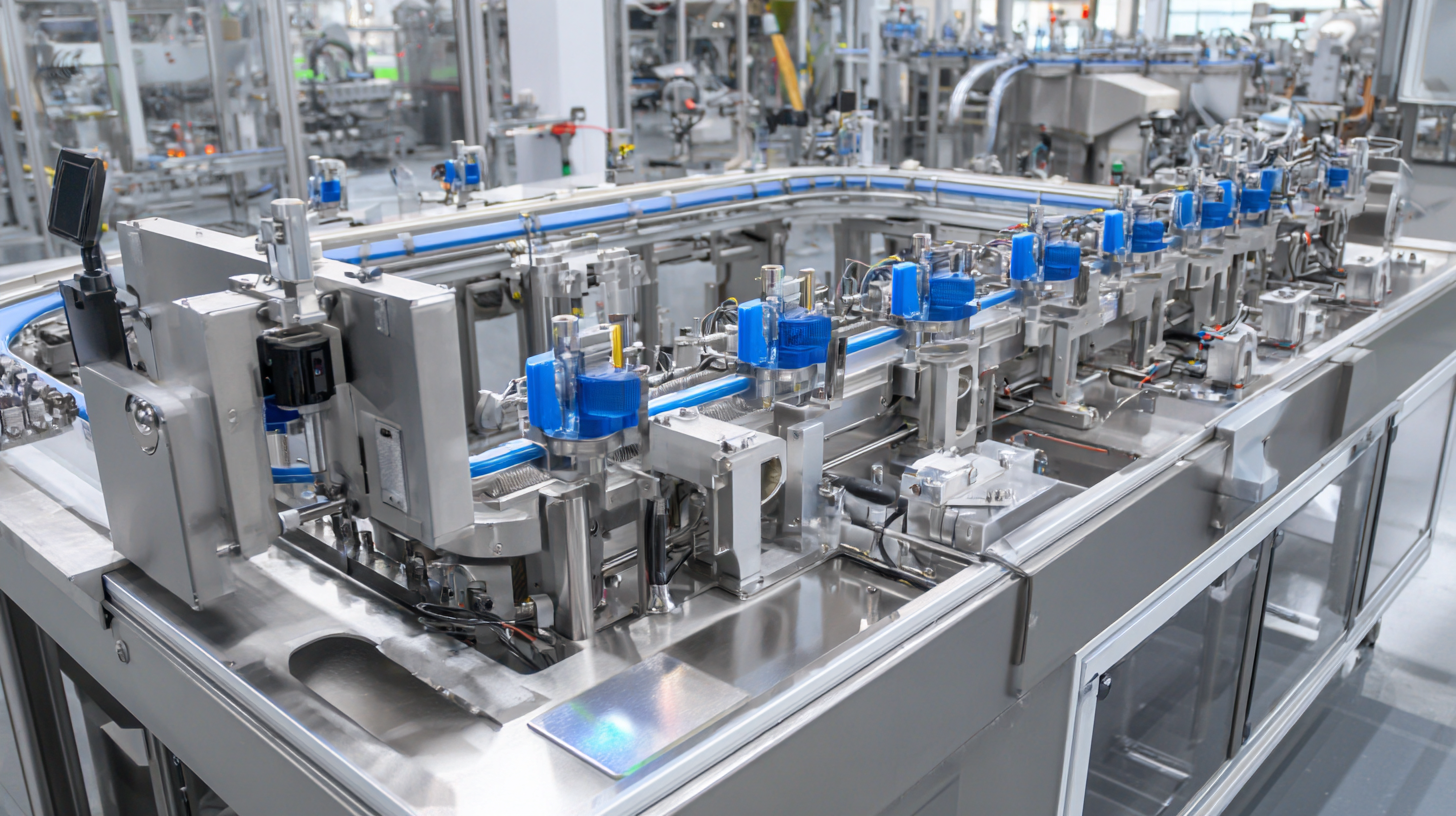

The evolution of packaging technology has become increasingly vital in today's fast-paced market. Embracing innovative shrink packaging machines signifies a critical step towards enhanced operational efficiency and sustainability. These advanced machines not only streamline the packaging process but also minimize material waste, aligning with the growing demand for environmentally-conscious practices. By integrating automation and smart technology, manufacturers can significantly reduce labor costs and improve throughput, allowing for faster production cycles.

Moreover, innovative shrink packaging machines offer unparalleled flexibility, enabling businesses to adapt swiftly to changing market trends and consumer preferences. This adaptability is essential in a landscape where customization and speed are paramount. With capabilities to handle various products—from food items to electronics—these machines cater to diverse industries, ensuring that companies remain competitive and responsive to customer needs. Adopting this cutting-edge technology is not just about keeping pace with the future; it is about leading the way towards a more efficient and sustainable packaging solution.

| Dimension | Value |

|---|---|

| Machine Speed (Packages/hour) | 1000 |

| Power Consumption (kW) | 5 |

| Shrink Film Type | Polyolefin |

| Operational Cost per Unit ($) | 0.05 |

| Setup Time (minutes) | 15 |

| Maintenance Frequency (months) | 6 |

| Space Requirement (sq ft) | 50 |

| Return on Investment (years) | 2 |

In today's fast-paced manufacturing environment, minimizing downtime on packaging lines is crucial for maintaining competitive advantage. Advanced shrink packaging machine technology plays a pivotal role in enhancing efficiency by streamlining operations and reducing the time spent on maintenance and adjustments. With features such as automated changeovers and real-time monitoring systems, these machines can significantly cut down on the delays that often plague traditional packaging setups. This innovative approach allows companies to maximize productivity by keeping the production flow uninterrupted.

Moreover, the integration of smart technologies, including IoT connectivity, provides manufacturers with valuable insights into machine performance and potential issues. Predictive maintenance capabilities enable teams to preemptively address problems before they lead to breakdowns, thereby further reducing unplanned downtime. By harnessing the power of data analytics, organizations can optimize their packaging processes, ensuring that every second counts in delivering products to market swiftly. This combination of innovation and technology not only enhances the operational efficiency of packaging lines but also contributes to overall profitability in an increasingly competitive landscape.

As businesses increasingly prioritize sustainability, eco-friendly options in shrink packaging solutions have emerged as a critical component of packaging line innovation. According to a 2023 report by the Smithers Pira, the global market for sustainable packaging is projected to reach $400 billion by 2025, driven by consumer demand for environmentally responsible products.

Shrink packaging, known for its versatility and efficiency, now offers materials that are recyclable or made from renewable sources, reducing environmental impact without compromising product protection.

Innovative shrink packaging machines are integrating advanced technology to accommodate these eco-friendly materials seamlessly. For instance, machines now utilize lower temperature applications that require less energy, aligning with initiatives to decrease carbon footprints.

The Intelligent Packaging Systems report indicates that companies adopting such technologies can reduce packaging waste by up to 30%, demonstrating that sustainability and efficiency can go hand in hand.

As manufacturers continue to explore these options, adopting eco-friendly shrink packaging not only enhances operational efficiency but also satisfies the increasing consumer preference for sustainable practices.

Upgrading to modern shrink packaging machines can significantly impact a company's bottom line, especially in terms of cost efficiency. According to a report from the Packaging Machinery Manufacturers Institute (PMMI), companies can see a reduction in labor costs by up to 30% when transitioning to automated shrink packaging solutions. This level of efficiency not only streamlines operations but also allows businesses to reallocate resources to other critical areas, ultimately enhancing productivity.

When considering the return on investment (ROI) for these upgrades, it's essential to evaluate both direct and indirect benefits. Modern machines often feature advanced controls that minimize material waste, with reports indicating a potential reduction of up to 20% in packaging film use. This decrease can lead to significant savings in raw material costs, creating a compelling case for investment. Additionally, the enhanced reliability of new technologies reduces downtime, as noted in studies by Freedonia Group, which suggest that improved machinery can increase overall equipment effectiveness by as much as 25%.

Tip: Before investing, conduct a thorough analysis of your current packaging processes and identify bottlenecks that modern machines can address. This will help pinpoint specific areas where efficiency gains can be maximized.

Tip: Engage with suppliers for demonstrations and performance benchmarks to compare your current operational costs against potential savings from new shrink packaging technology before making a decision.

In today's rapidly evolving market, adapting packaging solutions to meet consumer demands is crucial for businesses aiming to thrive. The recent surge in the metalized flexible packaging market highlights a growing inclination towards sustainability and functionality, driven by innovations in materials like plastic, paper, and aluminum foil. As consumers become more environmentally conscious, packaging producers are prioritizing the development of recyclable and compliant flexible packaging solutions, which can enhance product shelf life while minimizing environmental impact.

Tips: Consider incorporating sustainable materials into your packaging strategy to appeal to the eco-conscious consumer. Additionally, flexibility in design and functionality will not only attract a broader customer base but also allow for quicker adjustments in response to market trends.

The European flexible packaging market, valued at USD 52.96 billion in 2025, is on a trajectory for significant growth by 2034. With a CAGR of 4.9% in the multilayer flexible packaging sector, companies are seeing the benefits of investing in innovative designs that cater to consumer preferences. The North American packaging market is also set for substantial expansion, emphasizing the importance of staying ahead in the competitive landscape.

Tips: Utilize market analysis to identify key trends that resonate with your target audience and leverage this information to develop tailored packaging solutions. Engaging with industry insiders can provide valuable insights into regulations and emerging sustainability trends that influence consumer choices.