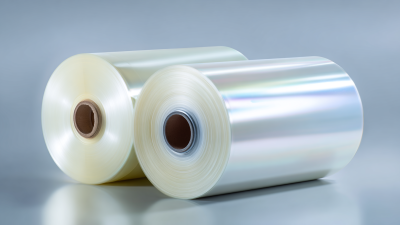

In an ever-evolving market where product safety and presentation are paramount, businesses are continually seeking innovative solutions to enhance their packaging strategies. One such solution that has garnered significant attention is Plastic Shrink Packaging. This versatile packaging method not only serves the essential function of protecting products from damage during transit but also plays a crucial role in improving their visual appeal on retail shelves.

In an ever-evolving market where product safety and presentation are paramount, businesses are continually seeking innovative solutions to enhance their packaging strategies. One such solution that has garnered significant attention is Plastic Shrink Packaging. This versatile packaging method not only serves the essential function of protecting products from damage during transit but also plays a crucial role in improving their visual appeal on retail shelves.

The benefits of using Plastic Shrink Packaging extend beyond mere protection, encompassing elements such as cost efficiency, sustainability, and ease of use. As companies strive to meet consumer demands while ensuring that their products remain secure and attractive, understanding how to effectively implement Plastic Shrink Packaging becomes essential.

This ultimate guide aims to delve into the key advantages and best practices associated with this packaging method, providing insights that can help businesses elevate their product protection game and enhance overall customer satisfaction.

Plastic shrink packaging has emerged as a vital solution for enhancing product protection across various industries. Its benefits include not only safeguarding products from environmental factors such as moisture and dust but also minimizing the risk of contamination during transport and storage. The tight seal created by shrink wrapping ensures that products remain intact and free from damage, making it an ideal choice for manufacturers who aim to maintain product integrity.

Plastic shrink packaging has emerged as a vital solution for enhancing product protection across various industries. Its benefits include not only safeguarding products from environmental factors such as moisture and dust but also minimizing the risk of contamination during transport and storage. The tight seal created by shrink wrapping ensures that products remain intact and free from damage, making it an ideal choice for manufacturers who aim to maintain product integrity.

The packaging market continues to grow, driven by the increasing demand for efficient and sustainable solutions. While plastic dominates the packaging landscape due to its versatility and cost-effectiveness, the environmental concerns surrounding plastic waste cannot be ignored. As such, the industry is exploring pathways to develop greener plastic packaging alternatives, focusing on materials that reduce environmental impact while providing the same level of protection. Innovations in biodegradable and recyclable materials are on the rise, offering promising alternatives without compromising product safety.

Plastic shrink packaging has become a vital component in protecting products across various industries, thanks to its impressive durability. One of the key features of this type of packaging is its ability to conform tightly to the contours of the product, which creates a secure cushioning effect. According to a report by the Freedonia Group, the demand for plastic packaging is expected to increase by 3.5% annually through 2025, highlighting the industry’s shift towards more protective solutions. The inherent sturdiness of polyethylene and polyvinyl chloride (PVC) materials provides resistance against moisture, dust, and physical impacts, enhancing the longevity of packaged goods.

Additionally, the layout of plastic shrink packaging allows for significant visibility while maintaining product integrity. Research from the Packaging Institute shows that 75% of consumers are influenced by packaging in their purchase decisions. The transparent nature of shrink film not only showcases the product but also acts as a barrier against environmental factors that can lead to spoilage or damage. Furthermore, the lightweight characteristic of shrink film reduces shipping costs, making it an economically sound choice for companies looking to enhance their product protection without incurring excessive expenses.

When comparing plastic shrink packaging to traditional packaging methods, it's essential to recognize the advantages that shrink wrap brings to the table. According to a report by Smithers Pira, the global flexible packaging market is expected to reach $300 billion by 2025, with plastic shrink packaging comprising a significant portion due to its efficiency and versatility. Unlike traditional packaging, which often relies on rigid materials, shrink wrap conforms tightly to the product, providing enhanced protection against dust, moisture, and damage during transit and storage.

Tip: Choose high-quality shrink film tailored for your specific products to optimize protection and presentation.

Another critical aspect is cost-effectiveness. A study published by the Flexible Packaging Association highlights that businesses can save up to 25% in material costs by switching to plastic shrink packaging. This is partly due to reduced material usage and improved shipping efficiency. Traditional packaging often takes up more space, leading to higher freight costs. In contrast, shrink-wrapped products are compact, allowing for more economical bulk shipping.

Tip: Maximize your savings by training staff on optimal packing techniques to leverage the benefits of shrink packaging fully.

Implementing plastic shrink packaging in your supply chain is a strategic move that can enhance product protection significantly. According to a report by Smithers Pira, the global demand for shrink film is expected to reach 5.1 million tons by 2025, underscoring its vital role in various industries. By employing best practices in shrink packaging, businesses can minimize product damage during transit, reduce waste, and improve shelf appeal.

When integrating plastic shrink packaging, consider these key tips: First, ensure that your packaging materials are compatible with the products being packaged. This will not only provide better protection but also enhance the overall presentation. Second, invest in proper machinery that can efficiently apply shrink film according to the specifications of your products. A well-optimized packing line can increase efficiency and reduce labor costs, which are crucial for maintaining competitive pricing.

Furthermore, regularly train your staff on the latest shrink wrapping techniques and equipment. A knowledgeable team can help identify potential issues before they escalate, resulting in a smoother operation. Data from the Freedonia Group indicates that companies that focus on employee training see a 20% decrease in packaging-related errors, ultimately leading to cost savings and improved customer satisfaction.

Plastic shrink packaging has become an essential tool across various industries, providing robust protection for products while enhancing their presentation. For instance, in the food industry, companies have successfully utilized shrink wrap to preserve freshness and extend shelf life. A notable case is a snack food manufacturer that adopted shrink packaging for its products, resulting in a significant reduction in spoilage during transportation and storage. This move not only decreased waste but also boosted customer satisfaction through improved product quality.

Plastic shrink packaging has become an essential tool across various industries, providing robust protection for products while enhancing their presentation. For instance, in the food industry, companies have successfully utilized shrink wrap to preserve freshness and extend shelf life. A notable case is a snack food manufacturer that adopted shrink packaging for its products, resulting in a significant reduction in spoilage during transportation and storage. This move not only decreased waste but also boosted customer satisfaction through improved product quality.

In the electronics sector, shrink packaging has effectively safeguarded fragile devices against dust, moisture, and physical damage. A successful electronics firm implemented plastic shrink packaging for its small gadgets, leading to a 30% decrease in returns due to damage. This case highlights the importance of protective layers in preserving product integrity, especially in markets with high shipping volumes.

Tips: When considering plastic shrink packaging, ensure that the chosen material does not interfere with the aesthetic appeal of the product. Additionally, evaluate the shrink process to maintain package uniformity and efficiency during production. Investing in quality shrink packaging equipment can also enhance the overall effectiveness and sustainability of your packaging solutions.