In the ever-evolving world of packaging, the Shrink Packaging Roll stands out as a versatile and efficient solution for businesses and individuals alike. As a beginner, understanding the intricacies of shrink packaging can help you leverage its full potential for protecting and presenting your products. This comprehensive guide will delve into the science behind shrink packaging, unpacking the materials, processes, and applications that make Shrink Packaging Rolls an invaluable asset in various industries. Whether you are looking to enhance your product's visibility, extend its shelf life, or simply ensure its safe transportation, grasping the fundamental principles of shrink packaging will empower you to make informed decisions. Join us as we explore how mastering shrink packaging can elevate your packaging game and streamline your operations, paving the way for both efficiency and sustainability.

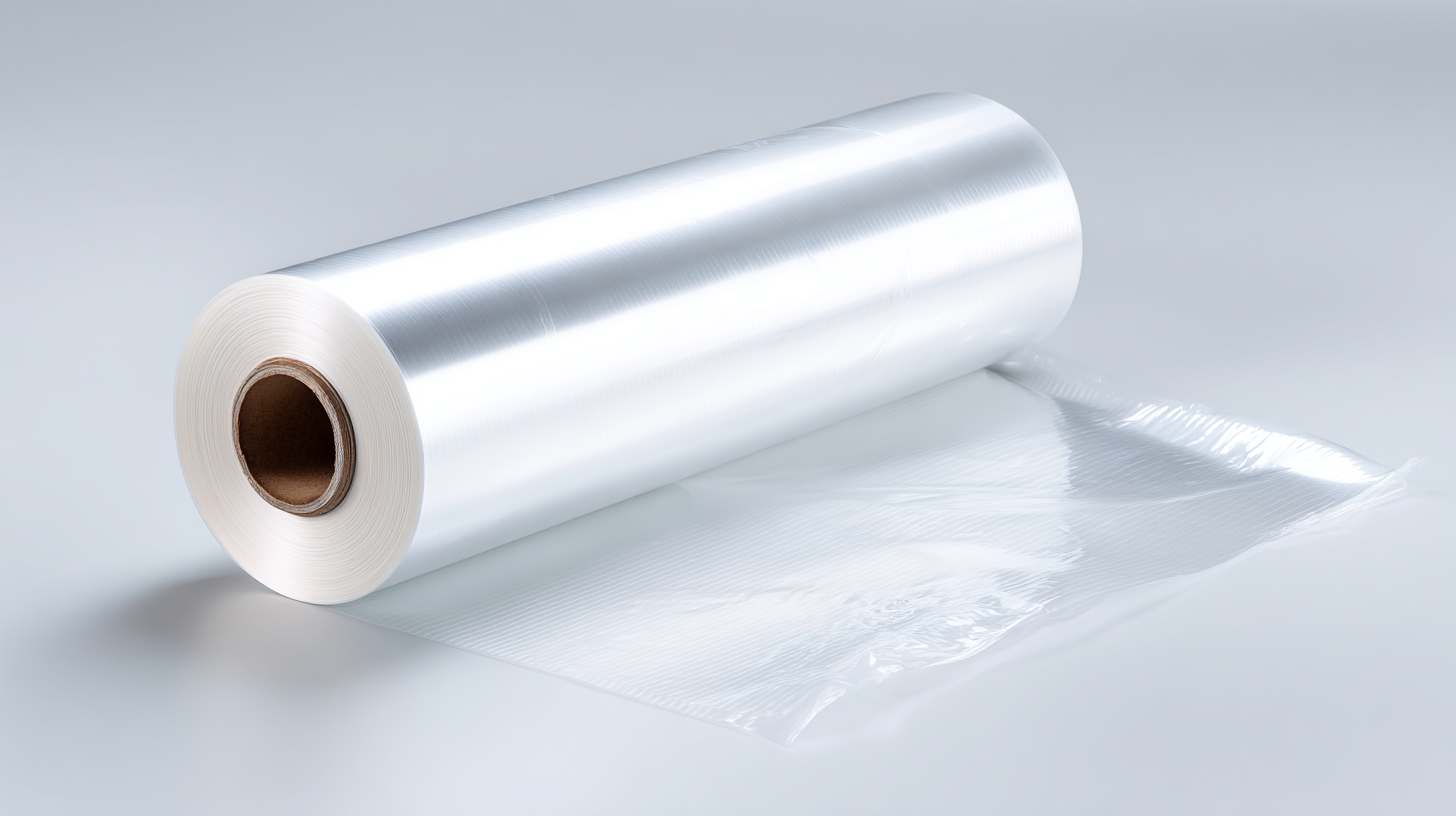

Shrink packaging is a versatile and effective method for protecting products and enhancing their presentation. For beginners looking to understand this process, it's essential to grasp the fundamental principles. Shrink packaging involves using a thermoplastic material that, when heated, shrinks tightly around the product it encases. This method not only provides a secure barrier against moisture, dust, and other contaminants but also gives items a professional appearance, making them more appealing to consumers.

One of the first steps in shrink packaging is selecting the right type of shrink film. Various materials, such as polyolefin, PVC, and polyethylene, offer different properties and suitability for specific products. After choosing the appropriate film, the next crucial aspect is understanding the equipment involved, including shrink tunnels and heat guns. These tools are responsible for applying the necessary heat to achieve the desired shrink effect. With practice and attention to detail, beginners can master the basic techniques of shrink packaging, ensuring their products are well-protected and market-ready.

Shrink film is a widely used packaging material that adheres tightly around products when heat is applied. This efficient wrapping solution is primarily made from various types of plastics, with polyethylene (PE) and polyvinyl chloride (PVC) being the most common. PE shrink film is favored for its excellent sealing properties, flexibility, and resistance to moisture, making it perfect for a variety of applications, from food packaging to household items.

Shrink film is a widely used packaging material that adheres tightly around products when heat is applied. This efficient wrapping solution is primarily made from various types of plastics, with polyethylene (PE) and polyvinyl chloride (PVC) being the most common. PE shrink film is favored for its excellent sealing properties, flexibility, and resistance to moisture, making it perfect for a variety of applications, from food packaging to household items.

Another popular material is PVC, known for its strong structural integrity and clarity, which allows for appealing packaging displays. It shrinks effectively at lower temperatures, providing a cost-efficient option for businesses looking to package products securely without risking damage. In addition to these, other specialty films such as polyolefin offer a balance of durability and clarity, making them ideal for both retail and industrial applications. Understanding these materials is crucial for anyone looking to utilize shrink packaging effectively, as each type has specific properties that cater to different needs and preferences in the packaging industry.

The shrink packaging process is an essential technique used in various industries to secure and protect products. It begins with selecting the appropriate shrink film, which is often made from materials such as polyethylene or polyolefin. The choice of film type is crucial, as it determines the durability and suitability for specific products. Once the film is decided upon, the next step involves cutting it to the right size, ensuring that it adequately covers the item to be packaged.

Next, the product is placed within the cut film, and the packaging is sealed, usually with a heat sealer. This step is critical, as a proper seal ensures that the package maintains its integrity during the shrinking process. After sealing, heat is applied, either through a heat tunnel or a handheld heat gun. The heat causes the film to shrink tightly around the product, conforming to its shape and providing a snug fit. This step not only enhances the appearance of the product but also protects it from dust, moisture, and tampering, making shrink packaging a vital choice for businesses looking to improve product presentation and security.

Shrink wrapping is a versatile packaging solution widely used across various industries, including food, retail, and manufacturing. In the food industry, shrink wrapping ensures the freshness of products while providing a tamper-proof seal. It is commonly used for packaging meats, vegetables, and beverages, allowing businesses to extend shelf life and maintain quality. The visually appealing presentation of shrink-wrapped products also enhances shelf impact, attracting consumers in retail settings.

Shrink wrapping is a versatile packaging solution widely used across various industries, including food, retail, and manufacturing. In the food industry, shrink wrapping ensures the freshness of products while providing a tamper-proof seal. It is commonly used for packaging meats, vegetables, and beverages, allowing businesses to extend shelf life and maintain quality. The visually appealing presentation of shrink-wrapped products also enhances shelf impact, attracting consumers in retail settings.

In manufacturing, shrink wrapping is essential for bundling items together, providing protection during transport, and ensuring that products arrive intact. It is often used for packaging tools, equipment, and consumer goods, safeguarding against dust and moisture. In addition, shrink wrapping is eco-friendly; many materials can be recycled, appealing to companies striving for sustainability.

Tips: When using shrink wrapping, ensure proper heat settings on your machine to avoid damaging the product. Additionally, consider using printed shrink film for branding purposes, which not only secures the product but also elevates its visual appeal on store shelves. Don’t forget to choose the right thickness of the shrink film based on the specific requirements of your product—too thin may compromise protection, while too thick can increase costs unnecessarily.

When selecting the right shrink packaging equipment and supplies, beginners should consider the specific needs of their products. Factors such as the size, shape, and material of the items being packaged will determine the type of shrink film required. For instance, polyethylene (PE) shrink film, which has seen a steady growth in consumption, is favored for its durability and clarity. It's essential to choose films that not only protect the products but also enhance their presentation on shelves, especially in competitive markets like dairy products where effective packaging can significantly influence consumer choice.

Another critical aspect is the equipment used for the packaging process itself. Beginners should assess whether they need a simple heat gun for small operations or a robust shrink tunnel for larger-scale packaging. Automation is becoming increasingly popular in the industry, as it enhances efficiency and consistency. Investing in equipment that can integrate with existing systems, such as inventory sortation tools, can streamline operations and ensure that products are packaged quickly and efficiently. By understanding these elements, newcomers to shrink packaging can make informed decisions that align with their business objectives and ultimately satisfy their customers.